Toyoda CNC Machines For Sale

What Makes Toyoda CNC Machines Stand Out?

World-Leading Grinding Technology: When it comes to OD CNC cylindrical grinders, Toyoda is the market leader worldwide. Even after decades of use, their patented TOYODA STAT® BEARING and floating plate ball nut technology guarantee long-term machining accuracy while removing bearing wear.

Modular Spindle Design: The industry-leading modular spindle technology found in every Toyoda CNC center offers unparalleled accuracy, repeatability, and uptime. The modular design minimizes expensive downtime by enabling speedy repairs when service is required.

Proven Reliability: Toyoda equipment is designed to withstand continuous operation in high-production automotive manufacturing. Meehanite cast iron bases with FEM analysis offer better thermal stability and damping while retaining accuracy under a range of production circumstances.

Fanuc Integration: Toyoda CNC machines use industry-standard Fanuc CNC controls, which offer recognizable interfaces that simplify operation and cut down on training time while maintaining reliable performance.

Toyoda CNC Machine Models

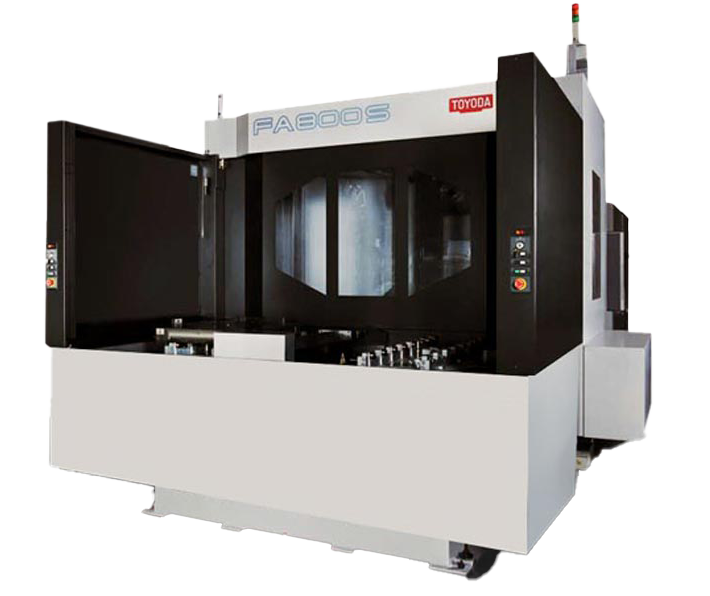

Horizontal Machining Centers

- FH400J/FH500J Series: Compact high-speed CNC horizontal machining center featuring 15,000 RPM spindles, 0.9-second tool-to-tool cycle times, and 2,362 ipm rapids. Direct drive B-axis with 360,000-position indexing. Available in CAT-40 and CAT-50 configurations.

- FH630SX-i/FH800 Series: Mid-to-large capacity machines with pallets from 24.8" to 31.5" square, handling workpieces up to 5,500 lbs. Features 8,000-15,000 RPM spindles, dual ball screws on Y/Z axes, and robust full-contact table clamping.

- FH1250SX: Heavy-duty HMC with 49.2" pallet, 6,000-15,000 RPM spindle speed options, cylindrical roller guides, and Meehanite cast iron construction for maximum rigidity.

Vertical Machining Centers

- FV965/FV1165 Series: Heavy-duty VMCs with four Y-axis box guideways and Meehanite bases. Travel ranges from 35.4" x 25.6" x 23.6" to 43.3" x 25.6" x 23.6". 8,000-12,000 RPM spindles, 25 HP motors, CAT-40 tapers.

- FV1365/FV1680 Series: Large-capacity models with tables up to 68.9" x 31.5", handling 4,400 lbs. CAT-50 tapers, 6,000 RPM geared heads, ideal for heavy workpieces.

- Stealth/AA Series (WELE): Modern Toyoda-WELE VMCs featuring two-speed geared heads, box-way construction, through-spindle coolant, and Fanuc 0i-MF Plus controls.

Grinding Machines

- GE Series: Universal cylindrical grinders with manually-swivelable wheelheads. Capacities from 19.69" to 78.7" between centers, swings to Ø25.9", weight capacities to 3,300 lbs. Features Toyoda Stat Bearing technology.

- GL Series: Production high-speed grinders for dedicated processes. Hydrostatic wheelhead bearings and way systems for continuous high-production accuracy.

- GU Series: Universal OD/ID grinders with swing-down ID attachments. Classic models like GUS32X100 provide versatile grinding in single setups.

Multi-Tasking Equipment

Gear Skiving Centers: Pioneering multi-purpose machines combining lathe spindles with rotary tables for skiving, turning, chamfering, milling, drilling, and tapping—all in single chuckings. Eliminates re-setup time and improves concentricity.

Toyoda Options and Enhancements

- Automation: MTConnect-compatible Flexible Pallet Automation (FPA) systems for enterprise integration and machine monitoring.

- Spindle Configurations: High-torque, high-speed (up to 15,000 RPM), and standard options are available. Through-spindle coolant systems available.

- Precision Features: Renishaw probing systems, tool presetters, in-process gauging, linear scales, and active thermal compensation.

- Workholding: Custom fixturing solutions, hydraulic chucks, multi-position rotary tables, and tombstone fixtures.

- Coolant Management: Chip conveyors, oil skimmers, paper filtration systems, high-pressure systems, and programmable nozzles.

How Toyoda Compares to Other Machine Tool Brands

Okuma

While both Okuma and Toyoda provide Japanese quality, Toyoda employs industry-standard Fanuc controls instead of Okuma's proprietary OSP. In the field of grinding technology, where Okuma is not as well-represented, Toyoda is the industry leader.

Mazak

Toyoda concentrates on machining centers and grinding, where they have developed core competencies, while Mazak offers a wider range of products. Superior build quality and thermal stability are characteristics of Toyoda.

Haas

Haas caters to budget-conscious work shops, while Toyoda uses heavier castings, better-quality components, and better thermal properties to build for demanding production environments.

DMG MORI

Although both hold prominent positions, Toyoda's grinding division outperforms DMG MORI. Because of its history in the automotive industry, Toyoda builds machines that are ideal for high-production settings.

Why Buy Used Toyoda from Premier Equipment?

We sell used Toyoda CNC machines with quality Japanese engineering at 40-70% below new equipment prices and decades of dependable service. Expert technicians inspect every machine in our inventory for spindle condition, way wear, control functioning, and mechanical integrity. We source used Toyoda models from compact FH400J HMCs to huge FV1680 VMCs, Toyoda with 4th axis and precision grinders through our global network, updating inventory regularly to ensure you locate the proper equipment.

Our used CNC experts with decades of Toyoda experience can help you evaluate applications, understand model variations, and choose the best equipment for your business. We provide detailed specifications, condition reports, and honest pricing on every equipment and facilitate inspections, demonstrations, and third-party evaluations. We coordinate shipping with professional riggers and recommend Toyoda-experienced installation companies to make equipment acquisition easy after the sale.

Used Toyoda Frequently Asked Questions

Are Toyoda and Toyota the same company?

Despite having a similar history to Toyota Motor Company, Toyoda Machine Works was established in 1941 as a distinct machine tool company. Toyoda and Koyo Seiko joined forces to establish JTEKT Corporation in 2006. Operating under the name JTEKT Machinery (formerly Toyoda), the machine tool division is now independent and focuses on bearings, machine tools, and automotive components rather than cars.

What makes Toyoda grinding machines superior to other brands?

Because of its patented TOYODA STAT® BEARING hydrostatic technology, which eliminates wear while maintaining exceptional accuracy, Toyoda has the largest global market share for OD CNC cylindrical grinders. After years of use, the floating plate ball nut system maintains its optimal positioning. When paired with FEM-optimized designs and Meehanite cast iron construction, Toyoda grinders retain precision for decades longer than rival machinery.

Can older Toyoda machines be retrofitted with modern controls?

Yes. Because of Toyoda's sturdy mechanical design, which frequently outlasts original controls, retrofits are financially appealing. Retrofitting Toyoda machines with contemporary Fanuc controls while preserving recognizable interfaces and incorporating Ethernet connectivity, more memory, and sophisticated programming is the specialty of numerous service providers. Additionally, spindle upgrades or rebuilds are made easier by the modular spindle design.

Resources

Toyoda Customer Care and Technical Support

JTEKT Machinery North America

Website: https://jtektmachinery.com

Technical Support & Parts: Available through regional service centers

Address: 316 W. University Drive, Arlington Heights, IL 60004

Phone: 847-253-0340

Fax: 847-253-0540

E-mail: info@jtektmachinery.com

Global JTEKT Corporation

Website: https://www.jtekt.co.jp/e

Headquarters: Kariya, Aichi, Japan

Toyoda CNC Machine Specifications

CNC Horizontal Machining Centers

| Machine Model | Travel (X, Y, Z) | Spindle | Pallet Size | Tool Capacity |

|---|---|---|---|---|

| Toyoda FA-450 | 17.72" x 17.72" x 19.69" | 12,000 RPM, 30 HP, CAT40 | 15.75" x 15.75" | 60 tools |

| Toyoda FA-550 | 21.65" x 21.65" x 23.62" | 10,000 RPM, 40 HP, CAT40 | 19.69" x 19.69" | 60 tools |

| Toyoda FA-630 | 24.80" x 24.80" x 25.59" | 8,000 RPM, 40 HP, CAT50 | 24.80" x 24.80" | 80 tools |

| Toyoda FH-450R | 17.72" x 17.72" x 19.69" | 12,000 RPM, 30 HP, CAT40 | 15.75" x 15.75" | 60 tools |

| Toyoda FH-550R | 21.65" x 21.65" x 23.62" | 10,000 RPM, 40 HP, CAT40 | 19.69" x 19.69" | 60 tools |

| Toyoda FH-630 | 24.80" x 24.80" x 25.59" | 8,000 RPM, 50 HP, CAT50 | 24.80" x 24.80" | 80 tools |

| Toyoda FH-800 | 31.50" x 31.50" x 31.50" | 6,000 RPM, 50 HP, CAT50 | 31.50" x 31.50" | 120 tools |

CNC Vertical Machining Centers

| Machine Model | Travel (X, Y, Z) | Spindle | Table Size |

|---|---|---|---|

| Toyoda FV-45 | 17.72" x 15.75" x 17.72" | 12,000 RPM, 20 HP, CAT40 | 19.69" x 15.75" |

| Toyoda FV-65 | 25.59" x 19.69" x 19.69" | 10,000 RPM, 30 HP, CAT40 | 29.53" x 19.69" |

| Toyoda FV-85 | 33.46" x 23.62" x 23.62" | 8,000 RPM, 40 HP, CAT50 | 37.40" x 23.62" |

| Toyoda FV-NPro | 17.72" x 15.75" x 17.72" | 12,000 RPM, 20 HP, CAT40 | 15.75" diameter |

CNC Lathes

| Machine Model | Max Swing | Max Length | Spindle | Chuck Size |

|---|---|---|---|---|

| Toyoda GL6-50 | 15.75" | 27.56" | 4,500 RPM, 20 HP | 8" |

| Toyoda GL6-100 | 15.75" | 51.18" | 4,000 RPM, 25 HP | 10" |

| Toyoda GE-4T | 17.72" | 35.43" | 4,000 RPM, 30 HP | 10" |