In the constantly changing world of manufacturing, Artificial Intelligence in CNC machine production is changing the way parts are designed, machined and produced. In this article, we look at the cutting edge technologies that are revolutionizing CNC machine shops, from CloudNC and Autodesk, and how AI will impact this sector in the future.

The Rise of AI in CNC Machining

AI adoption in the manufacturing industry is no exception to the long history of technological innovation in the manufacturing industry. As traditional CNC machining is extremely precise and effective, the process is still generally manual, programmed, and setup, which can be slow and subject to error. But then along comes AI — a game changer which promises to automate many of these processes, thereby increasing productivity, accuracy and overall efficiency.

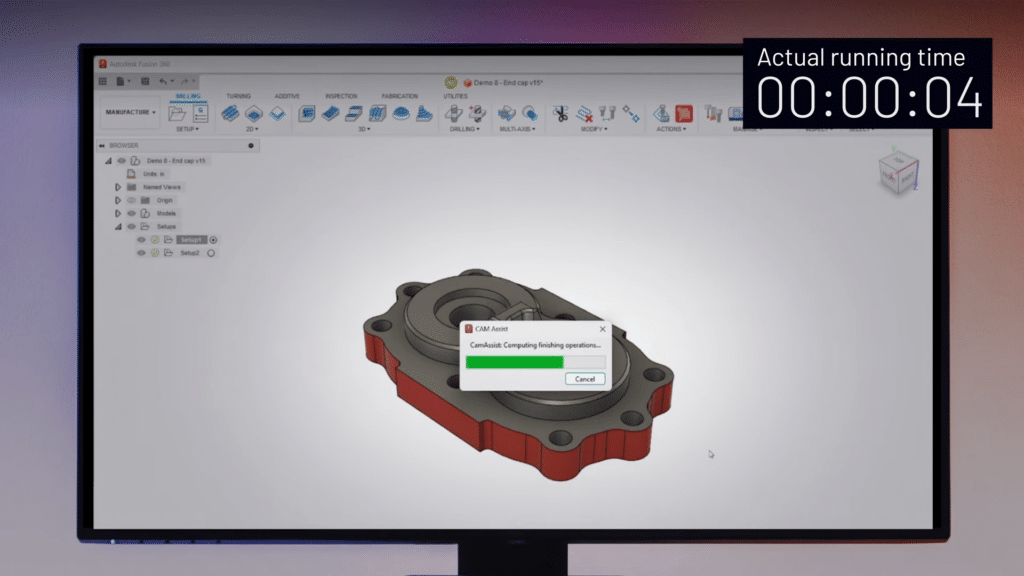

A pioneer in this field is CloudNC, which has developed a tool called CAM Assist, which uses AI to generate machining strategies for 3 and 2 axis CNC machines. It automates the complex task of generating optimal machining paths, something that has traditionally been a time consuming and expertise demanding process.

How CAM Assist Works

A prime example of how AI can make CNC machining faster is CAM Assist by CloudNC. Here’s a breakdown of how it operates:

- Automated Machining Strategies: The CAM Assist system analyzes the geometry of the part to be machined using AI algorithms in order to design the most efficient machining strategy. Here we find how to determine the optimum tool path and necessary feed rates, and other critical machining parameters which influence the machining process.

- Real-Time Optimization: In real time, the software adjusts machining parameters based on how it can constantly optimize the process running to ensure optimal quality and speed.

- Error Reduction: CAM Assist automates the programming process, thereby minimizing the possibility of human error, a typical problem in conventional CNC programming.

- Compatibility: It functions perfectly with numerous CNC machines making it a handy option across different manufacturing set ups.

The Future of AI in CNC Machining

The impact of AI on CNC machining is going to grow as AI grows. AI powered predictive maintenance can predict when CNC machines will need servicing, reducing downtime and increasing overall equipment efficiency. AI driven lenses and cameras also improve quality control by observing machining processes in real time, providing near instant detection of deviations in specification and alerting operators to rectify if necessary.

New customization and workforce collaborating in machining are also being driven by AI. AI allows for fast changes in machining strategies necessary to manufacture highly personalized parts with incredibly high accuracy. Instead of substituting for human workers, AI is becoming an amplifier of the workforce (in this case, the machinist) by assuming repetitive tasks not requiring skilled handiwork, and allowing skilled machinists to concentrate on the complex, creative and high value aspects of being a machinist.

Implementing AI in Your CNC Machine Shop

CNC machine shop owners, managers, and executives contemplating adoption of AI need to take a moment and plan and make some wise decisions to get the most from it. Begin by identifying just what your shop needs, and where AI could most positively impact your operations, including programming, machining strategy optimization and quality control. That foundation with that understanding you now have, lets you target which AI solutions best fit what you want to do.

Training is equally important since even the top AI systems will not operate at full potential without trained hands. Also, pick AI tools and software that work with your existing infrastructure; known options like Fusion 360 is versatile, but might require some setup and integration before it’s ready to go. Lastly, make sure you keep an eye on and tweak the performance of your AI system to make it better and better, resulting in an ever improving AI driven environment in your shop.

Conclusion

The integration of AI into CNC machine production is not only a trend but a change that will shake the whole manufacturing sphere. Tools like CAM Assist from CloudNC and the AI driven features of Autodesk’s Fusion 360 enable CNC machine shops to achieve previously unattainable levels of efficiency, accuracy and customization.

Looking to the future, it will be clear that AI will stay to be the integral part of the manufacturing landscape. Embracing these technologies will allow manufacturers to be at the forefront of innovation and ready to meet the ever changing demands of a rapidly changing world.