Managing an unpredictable mix of parts, materials, and production volumes while preserving profitability is one of the hardest balancing acts in manufacturing, and running a successful machine shop requires mastery of these abilities. Job shops require equipment that can quickly transition from a medical device prototype in the morning to automotive tooling in the afternoon and aerospace components the following day, in contrast to production shops that repeatedly run the same parts.

Because of this need for adaptability, choosing the right equipment is essential. You will lose out on lucrative work if you select machines that are too specialized. You’ll struggle with quality and efficiency if you choose equipment that isn’t capable enough. Haas-branded CNC machines are the perfect balance of value, dependability, and versatility for the majority of job shops, keeping the lights on and the work moving.

After 37 years of assisting job shops in the USA in locating the appropriate equipment, we have direct experience with the Haas machines that consistently produce results in low-volume, high-mix settings.

Let’s break down the best Haas CNC options and how to maximize their versatility.

Understanding What Job Shops Actually Need

Let’s first determine what makes job shop requirements distinct before getting into particular machines. In contrast to specialized production settings, machine shops encounter a number of unique difficulties:

- Unpredictable Work Mix: One day you may machine stainless steel, then aluminum, and then exotic alloys. This material diversity must be handled by your equipment without the need for specialized tooling or extensive reconfiguration.

- Varying Part Sizes: Parts ranging from tiny brackets to substantial structural elements are frequently encountered in job shops. Your ability to bid is significantly limited by a machine that can only handle one size range.

- Quick Turnarounds: Customers anticipate small batches to be delivered quickly. This implies that your machines must be simple to set up, program rapidly, and transition between tasks without requiring long breaks.

- Cost Sensitivity: Every machine hour must produce revenue for a variety of uses. You can’t afford idle equipment because it’s too specialized, and you can’t waste time battling machines that are too complicated.

- Operator Skill Levels: Machine shops frequently lack the funds to hire a master machinist for each machine. While providing advanced capabilities when required, your equipment must be user-friendly enough for less experienced operators.

These specifications suggest machines with wide capabilities, simple operation, and demonstrated dependability—exactly what Haas has been known for since 1983.

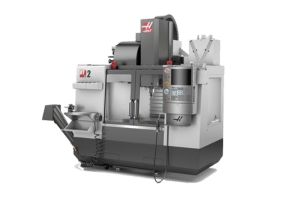

The Clear Winner for Job Shop Milling: Haas VF-2 and VF-3

Two Haas vertical machining centers, the VF-2 and VF-3, have been repeatedly shown to be the workhorses of versatile manufacturing after hundreds of job shop operations were examined.

Why the VF-2 is the Job Shop Standard

For good reason, the Haas VF2 is the most widely used vertical mill in America. It can handle between 75 and 80 percent of normal job shop work with its 30″ x 16″ x 20″ work envelope without taking up too much floor space or going over your budget.

Everything from medium-sized mold bases to tiny valve bodies can be machined effectively thanks to this sweet spot sizing. Most vise setups with space for multiple parts can be accommodated by the 30-inch X-axis travel, and standard fixtures and tooling can be adequately cleared by the 16-inch Y-axis and 20-inch Z-axis.

Excellent surface finishes in aluminum are produced by the Haas VF-2’s standard 8,100 RPM spindle (10,000 RPM on more recent models), which also provides sufficient torque for steel and other harder materials. When time is of the essence, the 30 HP spindle motor allows you to make aggressive cuts, but it is still manageable for delicate finishing tasks.

The VF-2’s 24-position automatic tool changer is perhaps its most significant feature for job shops. Without constant manual intervention, this capacity manages the variety of tools required for full part processing. Specialty cutters, drills, taps, chamfer tools, and general-purpose end mills can all be loaded simultaneously.

When to Step Up to the VF-3

The Haas VF3 expands the work envelope to 40″ x 20″ x 25″ for manufacturing facilities that frequently deal with larger parts or require more Y-axis travel. Work that would otherwise require costly outsourcing or multiple setups is made possible by this additional capacity.

The Haas VF3 expands the work envelope to 40″ x 20″ x 25″ for manufacturing facilities that frequently deal with larger parts or require more Y-axis travel. Work that would otherwise require costly outsourcing or multiple setups is made possible by this additional capacity.

When working with larger vise setups, multiple-part fixtures, or parts that need more clearance for tooling, the 10-inch Y-axis advantage is especially helpful. Taller workpieces, deeper cavities, and more comfortable tool clearance are all made possible by the extended Z-axis.

Because the VF-3 uses the same control system, programming methodology, and operational logic as the VF-2, it is particularly intelligent for expanding job shops. Programming transfers directly, and operators move between machines with ease. Training time and programming errors are significantly decreased by this consistency.

Both devices make use of Haas’s Next Generation Control (NGC), which has an easy-to-learn interface compared to Fanuc or Siemens controls. Experienced machinists value the logical menu structure and useful on-screen instructions, while new operators become more productive more quickly.

The Versatile Turning Solution: Haas ST-20 Series

Job-shop facilities require equally capable turning equipment, but mills receive the majority of the attention. With a footprint and price point that makes sense for job shop economics, the Haas ST-20 turning center has become the standard option for good reason.

Job-shop facilities require equally capable turning equipment, but mills receive the majority of the attention. With a footprint and price point that makes sense for job shop economics, the Haas ST-20 turning center has become the standard option for good reason.

The ST-20 can handle the great majority of turned parts found in job shop work thanks to its 15.75″ swing diameter and 20.5″ between centers. More significantly, it is equipped with a 12-position turret and live tooling capability by default, which turns it from a basic lathe into a full-featured turning solution.

With live tooling, you can execute cross-drilling, off-center features, and milling operations without having to move components to another machine. This mill-turn capability allows job shops to complete complex parts in a single operation, improve accuracy (without losing setup reference), and speed up cycle times.

In addition to enabling features like keyways, oriented drilling, and hexagonal sections, the servo-driven C-axis offers accurate positioning for mill-turn operations. When quoting complex parts that would otherwise require multiple machines and setups, this flexibility proves invaluable.

The ST-30 increases the swing to 23.6″ for job shops that handle larger diameter work while keeping the same operational strategy and control system. Because Haas turning centers are all the same, operators who become proficient with one model can operate any machine in the ST series with ease.

Tool Changer Capacity: Finding the Right Balance

Your shops versatility is greatly impacted by tool changer size, but larger isn’t always better. You can choose equipment more wisely if you are aware of the trade-offs.

Standard 24-Position Changers

The majority of job shop applications are effectively handled by the 24-position tool changer found on standard VF-2 and VF-3 machines. You can allot the following for standard milling operations:

- 6-8 positions for roughing end mills (various sizes)

- 4-6 positions for finishing end mills

- 4-5 positions for drilling tools

- 3-4 positions for tapping tools

- 2-3 positions for boring or specialized operations

- 2-3 positions for spare or backup tools

For the majority of jobs, this distribution handles full part processing without the need for tool changes in the middle of the program. Strategic tool selection and clever programming that optimizes the usefulness of each tool are crucial.

Upgrading to 40-Position Changers

Haas provides 40-position side-mount tool changers for machine shops that handle particularly complex parts or wish to reduce tool changes between jobs. This increased capacity offers a number of benefits:

You can switch between jobs without having to reload tools by loading entire tool libraries for particular part families. For recurring clients whose parts need specialized tooling, this is extremely beneficial.

More backup tools can be used thanks to the increased capacity, which lessens the effect of tool failure on unattended operations. Find machines with different tool changer configurations by looking through our Haas inventory.

But the 40-position changer costs more, takes up more floor space, and takes a little longer to change tools. The standard 24-position changer is more cost-effective for many job shops, particularly when paired with strategic tool management.

Versatility vs. Specialization: Making the Right Trade-Offs

There is a fundamental conflict between specialized capability and versatility in job shops. Your profitability and competitive position depend on knowing where to draw these lines.

When Versatility Wins

Broad-capability machines make sense when:

- Your clientele includes people from a variety of industries with a range of needs.

- Usually, part volumes vary from one to fifty pieces per run.

- You frequently quote new parts where capability questions arise

- There isn’t enough floor space in your shop for several specialized machines.

- You must make the most of every piece of equipment.

The combination of the VF-2/VF-3 and ST-20 offers outstanding coverage in these situations. You can bid with confidence on the majority of opportunities because these machines can handle 85–90% of typical job shop work efficiently.

When Specialization Pays Off

Profitability can be increased through strategic specialization as your shop expands and work patterns settle:

High-Speed Machining: A specialized high-speed machine such as the Haas VF-2SS (with a spindle rotating at 12,000 RPM) significantly enhances cycle times and surface finishes if you frequently work with aluminum or other non-ferrous materials.

Large Part Capacity: Purchasing a VF-4 or larger is advantageous for shops that consistently receive large-part work. This should only happen, though, after smaller machines have reached a high level of utilization.

Production Runs: Adding specialized production machines with automated part loading that can operate unattended is something to think about when you secure longer production runs. But keep up your adaptable equipment for prototype and fast-turn work.

Building a versatile foundation is crucial, followed by the addition of specialized capability when certain job demands warrant it.

Real-World ROI: How Job Shops Profit from Haas Versatility

Let’s look at specific instances of how Haas adaptability contributes to job shop profitability:

Case Study: Midwest Precision Components

This 12-person machine shop serves industrial, agricultural, and automotive clients with three VF-2 mills and one ST-20 lathe. With an average equipment utilization rate of 82%, their four machines generate $1.8 million in revenue annually.

The owner says, “The VF-2 handles literally everything we quote.” “We’re machining 17-4 stainless valve bodies one minute, followed by 6061 aluminum brackets and 4140 steel fixture components the next. Different speeds and feeds, but the same machine and setup method. Our competitive advantage is that adaptability.”

They have reduced training time, streamlined tooling inventory, and established programming consistency by relying on Haas equipment, which lowers errors and expedites delivery.

Case Study: Aerospace Prototype Solutions

With two VF-3 mills and one ST-30 lathe, this eight-person specialty shop specializes in aerospace prototypes. In particular, they selected larger machines to manage test fixtures and awkward prototype assemblies.

The shop manager notes, “We see everything from tiny sensor housings to large test fixture components.” “With the help of the VF-3, we can manage those big parts without wasting machine time on smaller tasks. We also receive the same support and dependability as any other machine because it’s still a standard Haas.”

Their ability to finish a variety of prototypes fast has led to premium pricing; clients appreciate their ability to complete complex parts quickly, so they charge 15–25% more than the going rate.

Setup Efficiency: Maximizing Haas Versatility

Owning multipurpose equipment only generates revenue if you can quickly transition between tasks. Successful job shops optimize Haas setup efficiency in the following ways:

Standardize Workholding

Invest in an extensive vise system that has part stops and standardized jaw positions. Kurt-style vises with repeatable positioning drastically cut down on setup time by allowing you to program using standard work offsets.

Establish a jaw inventory for common part sizes and standardize chuck jaw sets for the lathe. Keep track of jaw positions to ensure consistent setups.

Develop Programming Templates

Make program templates for common tasks like finishing passes, drilling patterns, pocketing, and face milling. These templates guarantee consistency while significantly accelerating programming.

Template creation is simple thanks to Haas’s user-friendly control. Templates for new parts can be quickly modified by even inexperienced programmers.

Implement Tool Management Systems

Keep tool cribs with pre-set tools neat and orderly. Make use of document tool offsets and high-quality tool holders (CAT40 for VF series). By being prepared, setup delays caused by offset measurements and tool searches are eliminated.

To further minimize machine downtime during setups, think about purchasing tool presetters that measure tool lengths and diameters offline.

Train for Versatility

Provide operators with cross-training on both turning and milling machinery. This training is effective because of Haas’s consistent control philosophy; operators who are accustomed to the VF series quickly become accustomed to the ST series.

Instead of causing bottlenecks at individual machines, this cross-training flexibility enables work to flow to available capacity.

Making Your Investment Decision

When selecting Haas machines consider this decision framework:

- Starting Out: For startups and small businesses, one VF-2 and one ST-20 offer remarkable versatility. This combination manages a variety of tasks while maintaining a fair initial investment. For shops just starting out, used machinery from reliable dealers offers especially good value.

- Established Shops: As the amount of work increases, upgrade to a VF-3 or add another VF-2. In the event that one machine needs maintenance, the backup milling machine removes bottlenecks.

- Growing Operations: Only after your versatile machines are operating at high utilization should you think about adding specialized capability (a horizontal mill, a larger capacity, or a high-speed machine). Choose the appropriate capacity for your stage of growth by looking through our Haas selection.

Conclusion: Versatility as Competitive Advantage

Versatility is essential to competitive success in machine shop manufacturing, not just because it’s convenient. Profitability is directly impacted by the capacity to deliver rapidly across a variety of part types, quote with confidence on a wide range of work, and maintain high equipment utilization.

Due to decades of demonstrated performance in these exacting conditions, Haas machines have earned their place as job shop favorites—not through marketing. The VF-2, VF-3, and ST-20 provide the ideal balance of value, capability, and dependability needed by prosperous job shops.

These machines continue to function when you need them most because of their simple control system, robust dealer support network, and excellent parts availability. Additionally, Haas machines outperform other brands in terms of value and capability, making them wise investments for shops looking to buy used equipment at any price range.

Ready to add versatile Haas capability to your job shop?

Discover inspected, ready-to-run machines from the biggest used CNC dealer in the USA by looking through our current Haas inventory. With flexible financing options and nationwide logistics support, our team of CNC experts can assist in matching the appropriate equipment to your unique job shop requirements. Reach out to Premier Equipment at our headquarters in Altamonte Springs, Florida, right now. We’re prepared to assist you in creating a more profitable and adaptable store.