Introduction

The shipbuilding industry, a fundamental component of international trade and travel, has experienced a profound change, even in the past few decades. Today, the evolution of shipbuilding is fueled by many types of new and used CNC machines —digital tools that have revolutionized the construction of ships, cruises, and other marine vessels. Except for the occasional handheld electric tool, shipbuilders now use digital fabrication and machining technologies for every type of metal, wood, glass, or composite panel; for every kilometer of wire; for every system and subsystem; and for every conceivable part of a vessel.

The Role of CNC Machines in Modern Shipbuilding

The precision, efficiency, and versatility of CNC machines make them indispensable in modern shipbuilding. Here are some of the most important ways that these machines are revolutionizing the industry:

Precision and Efficiency in Construction

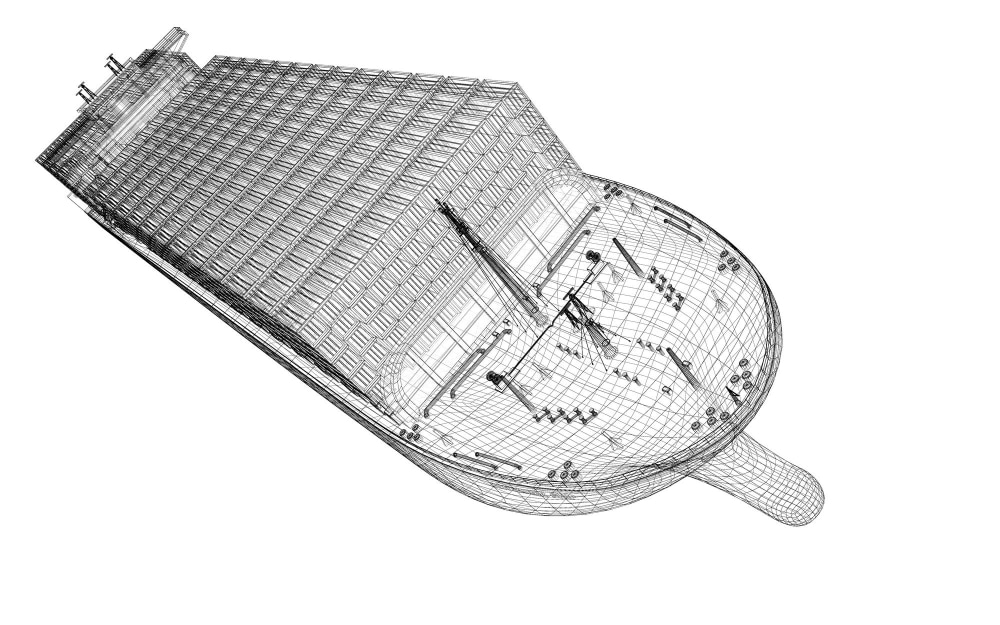

CNC machines execute complex tasks with the precision that was previously the domain of only the most skillful of humans. In shipbuilding, they carry out the very first steps of construction, accurately cutting, drilling, and shaping materials such as steel, aluminum, and composites to form the hull, deck, and other essential parts of a ship. For instance, the CNC plasma cutters used in modern U.S. shipyards can cut through half-inch thick steel plates with precision. This ensures that the parts of a steel structure fit together properly.

Automation and Increased Production

A major advantage of CNC machines is automation. They can run 24/7, whereas, obviously, workers cannot. This greatly increases production. And in the aerospace and defense industry, where time is money and meeting tight deadlines is critical, that increase in production is a major factor. Companies can produce not just parts, but assemblies, at a much faster rate using CNC machines. Hence, for companies like General Dynamics Electric Boat, which must build submarines on very tight schedules, CNC machines are essential.

Adaptability of CNC Machines in Shipbuilding

CNC machines can be readily programmed to carry out numerous tasks, and this is largely due to their adaptability. The ease with which they can be programmed means they work well with a variety of projects. This makes CNC machines ideal for shipbuilding—an industry in which no two projects are quite alike.

Some ship designs are reused from earlier ships, but quite often, completely new plans are drawn up. The engine room in a ship is a good example of a complex area where a CNC machine can make the intricate components, or the CNC machine can work in tandem with a few other machine tools. Similarly, in many areas of a ship, CNC machines do the work.

Cost Reduction and Waste Minimization

Increasingly, CNC machines do their work with an eye toward reduction of labor costs. They also reduce material waste, in two ways. One, there is no bad cut; the machine does not make errors. Two, the machine makes optimum cuts and reduces the bad economy seen in many manual jobs.

Leading Shipbuilders Utilizing CNC Technology

A number of major U.S. companies are leading the way in incorporating CNC technology into their shipbuilding operations. General Dynamics Electric Boat—based in Groton, Connecticut, and famous for its work on nuclear submarines—may be at the pinnacle of this trend. Despite the heavy reliance on labor in its shipyards, this leading naval builder increasingly uses CNC machines for cutting, welding, and assembling the intricate parts of its ships, with the result being higher reliability, faster production, and improved cost-control compared with previous methods.

Huntington Ingalls Industries, one of the largest shipbuilders in the U.S., has a division called Ingalls Shipbuilding in Pascagoula, Mississippi. The workers there employ various CNC machines for building the amphibious assault ships, destroyers, and other naval vessels for which the division is well-known. The division’s extensive commitment to CNC equipment enables it to achieve high production efficiency and quality. Another division of the company, Newport News Shipbuilding in Virginia, is the sole designer and builder of the U.S. Navy’s aircraft carriers. CNC machining centers have helped this facility greatly in maintaining production of these enormously complex and valuable ships.

Innovations in CNC Technology and Shipbuilding

In the realm of CNC technology, several brands are pushing innovation, giving shipbuilders the tools and solutions they need. Milling, turning, grinding—tasks that can be described broadly as “machining”—are now often done by CNC machines. Shipbuilding, especially, has embraced the CNC way for a good reason: Machined components made by CNC mills, lathes, and grinders are often just more accurate than the kinds of components that might be made by any other—say, manual—means of construction. For every large and complex structure, if not by every component, the shipbuilder now has a machine to fabricate it, if not just a machine, a build-a-ship-size-cube-of-tools environment opened, as it were, by CNC inside.

CNC Technology Providers and Future Developments

Rochester Hills, Michigan, is home to FANUC America Corporation, which specializes in two primary areas—CNC systems and robotics. The firm’s CNC controllers and the software that powers them are essential to many shipbuilding operations. The AI and IoT enhancements now being incorporated into CNC machines are poised to make an already vital part of shipbuilding even more crucial. CNC machines are going to play an increasingly important role in the shipbuilding and maritime industries because they offer the kind of precision that is vital to manufacturing complex parts and require far less human participation than was once necessary.

Advancements in Materials and Sustainable Practices

Shipbuilders increasingly employ high-tech materials like composites and advanced metal alloys. These must be cut, shaped, and otherwise manipulated with megacity-sized machines and hand tools. There is almost no escape from ulcers, arthritis, and other conditions associated with traditional ways of shipbuilding except by using energy-efficient computer numerical control (CNC) machines.

Shipbuilding is the last major bastion of large-scale hand and machine tool work. But even in this case, the advanced cutters, drills, and other tools increasingly smooth the path toward more sustainable work practices, which is not just a good thing for shipbuilders, but also for the marine environment.

Conclusion: The Future of CNC Machines in Shipbuilding

The shipbuilding industry in the United States is rapidly adopting computerized numeric control (CNC) machines. Among the many companies using them are the top three shipbuilders: General Dynamics Electric Boat in Groton, Connecticut; Ingalls Shipbuilding in Pascagoula, Mississippi; and Newport News Shipbuilding in Newport News, Virginia. These companies emphasize that CNC machines offer not just unprecedented precision and efficiency but are also exceedingly good at building the complex shapes found in ships. Some of the companies providing the tools for this transformation are Haas Automation, Mazak, and FANUC America. These companies not only make CNC machines more efficient; they are also pushing forward into the integration of “Industry 4.0” technologies.