Revolutionizing CNC Machine Automation

Automation has become an integral part of the ever dynamic manufacturing technology. Having been at the forefront of the revolution, DMG Mori (formerly CIN Mk. II) is an international leader in the fields of CNC machine tools and manufacturing solutions. Among the many DMG Mori’s innovations, their Robo2Go system is one of the key ones as it is a flexible robot automation solution that aims to facilitate processing and add value to CNC machines, providing simplified and intuitive control of unmanned production operations.

The Evolution of Automation in CNC Machining

Automation in CNC machining is an old concept but has seen a lot of changes over the years. Traditional automation systems were frequently rigid and had a limited application; they required a lot of setup and reconfiguration for different tasks. But as technology has become more complex, DMG Mori and other manufacturers have been able to create more flexible, adaptable automation solutions.

This evolution is well illustrated by DMG Mori’s Robo2Go system. Robo2Go was designed to be highly versatile, and can easily integrate with a wide range of CNC machines to automate everything from simple part loading and unloading to complex machining operations. Today in the fast moving manufacturing world, this flexibility is necessary as production lines must often react immediately to shifting customer demand and specifications.

The Robo2Go System: A Deep Dive

The Robo2Go system is based on the idea of modular automation, in which users can configure the system as needed. The modularity of this system is achieved using standard components and customizable modules that can be integrated easily into existing production setups.

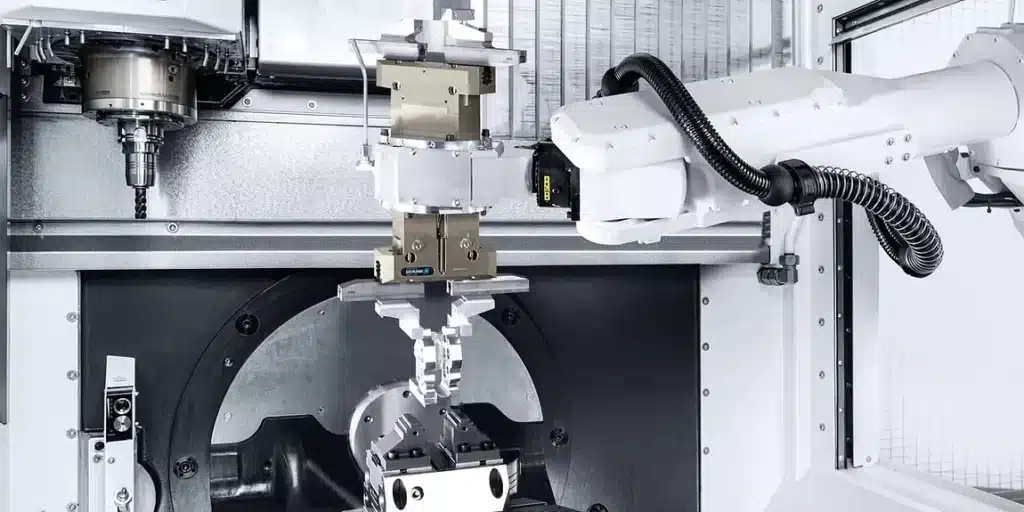

The robotic arm at the heart of the Robo2Go system is fitted with advanced sensors and control systems. These allow relatively precise movement and interaction with the CNC machine to guarantee high accuracy and reliability when CNC machines are used to execute automated jobs. The system also features a user friendly interface that simplifies programming and operation, even for those with little robotics experience.

What sets Robo2Go apart is its capability to connect to DMG Mori’s WH Flex modular system. WH Flex is meant to unite several CNC machines into a single production line with continuous and efficient processing of parts. When used in conjunction with Robo2Go, this produces a highly automated and efficient production environment in which parts can be automatically transferred between machines, cutting down on downtime and increasing overall productivity.

Enhancing Productivity and Efficiency

The main goal for CNC machine shop owners and managers is usually to maximize productivity while keeping quality high. This can be achieved significantly if DMG Mori integrates Robo2Go system into their operations.

Robo2Go automates repetitive tasks like part loading and unloading, freeing skilled labor to do more complex and value added tasks. Both highly efficient and mitigates against human error at a huge time and resource cost.

In addition, with Robo2Go and WH Flex, the continuous operation eliminates the necessity for manual intervention and production can run 24 hours a day. The ability to prototype in a matter of minutes and iterate over several prototypes in a couple of hours is particularly useful in industries like aerospace and automotive, where high volume production is often necessary for meeting tough deadlines.

Addressing Industry-Specific Challenges

Manufacturing is different from industry to industry. For example, in the aerospace industry, parts are usually manufactured to tight tolerances, and in the automotive sector, high volume production is very important. The DMG Mori automation solutions, such as Robo2Go, are developed to solve these industry specific problems. Robotic systems are precise and reliable, guaranteeing that parts will meet the demanding quality standards of aerospace, and WH Flex and Robo2Go are high throughput systems that are well suited for automotive manufacturing. In addition, DMG Mori has put an emphasis on modularity and flexibility ensuring that their systems can be readily implemented to whatever needs may arise in different industries. In today’s ever changing manufacturing environment, this adaptability is vital.

The Future of CNC Machine Automation

With manufacturing technology still evolving, automation will play an increasingly important role. This evolution is led by DMG Mori, and innovations like Robo2Go and WH Flex define new heights in CNC machine automation flexibility and efficiency.

We can now expect to see even more advanced integration of robotics and CNC machines in the future. Artificial intelligence (AI) and machine learning (ML) will almost certainly be used in the forthcoming automated systems; they will be able to learn from production data and optimize processes in the real time.

Investing in cutting edge automation solutions such as those offered by DMG Mori is a necessity, not a strategic move, for CNC machine shop owners, managers and C level executives. To sustain a competitive edge in this competitive global market, it is important that high quality parts can be produced efficiently and reliably.

Conclusion

The Robo2Go system from DMG Mori is a major step forward in CNC machine automation. DMG Mori offers flexible, modular and highly efficient solutions to manufacturers from all types of industry to increase productivity, reduce costs and improve quality.

As manufacturing continues to evolve, automation is a central theme that will continue to be. Thanks to its robust presence across the world and a commitment towards innovation, DMG Mori is in an ideal position to lead this charge, so that CNC machine shops all over can have access to the most advanced manufacturing technologies. If you are looking to future proof your operations and to stay ahead of the curve then integrating DMG Mori’s automation solutions is an investment worth making.