Haas VF-2 vs Mazak VTC-200 CNC Mill Comparison

The ultimate matchup between Japan’s precision engineering masterpiece and America’s most popular CNC mill

The Haas VF-2 and the Mazak VTC-200 are the two models that we frequently hear about when we receive calls from clients who are trying to decide between used CNC mills. We have sold and evaluated both machines for 37 years, and we have witnessed them operate in every kind of shop, from Fortune 500 production floors to startup garages.

Although they are both superb machines, their ideologies are essentially different. Simple, dependable, and supported by the best support system in the business, the Haas VF-2 epitomizes American pragmatism. Fast, precise, and constructed to strict specifications that put performance above simplicity, the Mazak VTC-200 is a perfect example of Japanese precision engineering.

Which machine is “better” for your particular requirements, operating style, and budget is the question, not which machine is “better” overall. We’ve witnessed stores struggle with machines that didn’t fit their needs or capabilities after making a poor decision. Additionally, we’ve witnessed perfect matches where the correct machine increased a shop’s profitability and productivity.

This comparison gives you a comprehensive analysis to make the best choice by slicing through the brand loyalty and marketing gimmick. Everything from programming complexity to resale values, from technical specifications to actual operating costs, will be covered. Our objective is to assist you in selecting the equipment that will best support your shop over the ensuing ten to fifteen years.

Technical Specifications: The Numbers Game

Let’s start with the raw specs that define each machine’s capabilities and limitations.

Haas VF-2 Specifications

Work Envelope:

- X-Axis Travel: 30 inches

- Y-Axis Travel: 16 inches

- Z-Axis Travel: 20 inches

- Table Size: 36″ x 18″

- Maximum Table Load: 1,400 lbs

Performance Specs:

- Spindle Power: 30 HP (40 HP optional)

- Spindle Speed: 8,100 RPM standard (12,000 RPM optional)

- Rapid Traverse: 1,000 IPM (all axes)

- Tool Capacity: 20 positions standard (40 optional)

- Tool Change Time: 2.8 seconds (chip to chip)

Machine Specifications:

- Machine Weight: 7,500 lbs

- Floor Space: 87″ x 102″ x 90″ (H)

- Power Requirements: 230V/460V, 3-phase, 60 Hz

Mazak VTC-200 Specifications

Work Envelope:

- X-Axis Travel: 31.5 inches

- Y-Axis Travel: 15.7 inches

- Z-Axis Travel: 20.1 inches

- Table Size: 36.2″ x 17.7″

- Maximum Table Load: 1,540 lbs

Performance Specs:

- Spindle Power: 30 HP

- Spindle Speed: 15,000 RPM standard

- Rapid Traverse: 1,417 IPM (X,Y), 1,181 IPM (Z)

- Tool Capacity: 30 positions standard

- Tool Change Time: 1.5 seconds (chip to chip)

Machine Specifications:

- Machine Weight: 8,818 lbs

- Floor Space: 99″ x 110″ x 96″ (H)

- Power Requirements: 200V/400V, 3-phase, 50/60 Hz

Specification Analysis

There are interesting variations in the specifications. The Mazak VTC-200 is quicker and more accurate; its spindle is running at 15,000 RPM and traverse speeds are faster. Haas VF-2 however is more skeletal since it is able to fit many spindle options and is able to change its tools modularly.

Work envelopes are near identical, except that the Mazak has slightly more space to move in the X-axis and the Haas more space to move in the Y-axis. This can be compared through the efficiency of the machines used and their features rather than on the lower functionality on how the machines can both handle workpieces which are of similar sizes and weight.

| Comparison Factor | Haas VF-2 | Mazak VTC-200 | Winner |

|---|---|---|---|

| SPECIFICATIONS | |||

| Work Envelope (X×Y×Z) | 30″ × 16″ × 20″ | 31.5″ × 15.7″ × 20.1″ | Tie |

| Spindle Speed | 8,100 RPM (12K option) | 15,000 RPM | Mazak |

| Rapid Traverse | 1,000 IPM | 1,417 IPM | Mazak |

| Tool Capacity | 20 (40 option) | 30 standard | Mazak |

| Tool Change Time | 2.8 seconds | 1.5 seconds | Mazak |

| PERFORMANCE | |||

| Aluminum Machining | Good | Excellent | Mazak |

| Steel Machining | Excellent | Good | Haas |

| Positioning Accuracy | ±0.0002″ | ±0.0001″ | Mazak |

| Surface Finish | 32-63 Ra | 16-32 Ra | Mazak |

| Cycle Time (Aluminum) | Baseline | 25-40% faster | Mazak |

| OPERATION | |||

| Programming Ease | Excellent | Good | Haas |

| Operator Training | 2-3 days | 1-2 weeks | Haas |

| Setup Complexity | Simple | Moderate | Haas |

| Versatility | Excellent | Good | Haas |

| SUPPORT & SERVICE | |||

| Service Network | 300+ locations | 80+ locations | Haas |

| Parts Availability | Same day | 1-3 days | Haas |

| Technical Support | 24/7 immediate | Appointment based | Haas |

| Service Cost | Lower | Higher | Haas |

| FINANCIAL | |||

| Used Price (2018) | $55K-65K | $60K-75K | Haas |

| Operating Costs | Lower | Higher | Haas |

| Maintenance Costs | $8K-12K/year | $10K-15K/year | Haas |

| Resale Value (5 yr) | 60-65% | 50-55% | Haas |

| BEST APPLICATIONS | |||

| Job Shops | ★★★★★ | ★★★☆☆ | Haas |

| Production Shops | ★★★★☆ | ★★★★★ | Mazak |

| Small Shops | ★★★★★ | ★★☆☆☆ | Haas |

| High-Precision Work | ★★★☆☆ | ★★★★★ | Mazak |

| Mixed Materials | ★★★★★ | ★★★☆☆ | Haas |

| Aluminum Focus | ★★★☆☆ | ★★★★★ | Mazak |

Score Summary

- Haas VF-2 Wins: 8 categories (Support, Operation, Cost)

- Mazak VTC-200 Wins: 7 categories (Speed, Precision, Performance)

- Ties: 1 category (Work Envelope)

The Bottom Line

The Haas VF-2 wins because it is more useful and costs less to own in the long run. The Mazak VTC-200 is better in terms of technical performance specs that are important for certain uses. You should choose between Haas and Mazak based on whether you value ease of use and support or cutting performance and accuracy.

Performance Comparison: Where The Rubber Meets The Road

Specifications only tell part of the story. How well these machines work in the real world depends on how well they can handle real-world cutting conditions, part complexity, and production needs.

Cutting Performance and Accuracy

Haas VF-2 Performance

The VF-2 works well with a wide range of materials and applications every single time. The 30HP spindle has enough power for most general machining tasks, and the optional 40HP upgrade works well for heavier cutting tasks. Positioning accuracy is usually ±0.0002″ with repeatability of ±0.0001″ on machines that are well taken care of.

In job shops where flexibility is more important than speed, the machine works great. It’s easy to get feed rates of 300 to 500 IPM when cutting aluminum. When cutting steel, the rate depends on the depth of the cut and the tools used. With the right programming and sharp tools, a surface finish of 32 to 63 Ra is normal.

Mazak VTC-200 Performance

The VTC-200’s spindle spins at 15,000 RPM, which makes it possible to cut aluminum and other light materials much faster than the Haas. Small-diameter end mills can run at the best surface feet per minute, which cuts down on cycle times for detailed parts by a lot. Positioning accuracy is usually better than ±0.0001″, and repeatability is usually better than ±0.00005″.

The Mazak often finishes jobs 25–40% faster than similar Haas machines when working with aluminum parts that have complex shapes. The faster rapid traverse rates (1,417 IPM vs. 1,000 IPM) cut down on the time that isn’t spent cutting on big parts that need to be changed a lot.

Material-Specific Performance

Aluminum Machining: The Mazak VTC-200 is the best CNC for working with aluminum. The high-speed spindle lets small tools cut at the right speeds, and the faster rapids cut down on the time it takes to cut through air. Machine shops that mostly make aluminum parts often see a 30% to 50% increase in productivity when they use the Mazak.

Steel and Harder Materials: Performance variance decreases with steel and other harder materials, where spindle speed is less important. The Mazak and Haas machines both work well with steel; however, the Haas’s simpler programming allows less experienced operators to set the best cutting parameters more easily.

High-Speed Machining: For true high-speed machining applications, the Mazak’s advanced look-ahead control and higher spindle speed provide clear advantages. Additionally, the Mazak VTC model maintains better accuracy at high feed rates and handles complex 3D toolpaths more smoothly, further exemplifying the benefits of Mazak’s technology.

Programming and Operation: Ease of Use Matters

The daily experience of programming and running these machines has a big effect on how productive and happy the operators are.

Haas VF-2: Simplicity and Accessibility

Haas Control System

The Haas control puts ease of use ahead of advanced features. The menu structures are logical and easy to understand, so new operators can get to work quickly. Programming functions include all the standard G and M codes, along with helpful prompts and error checking.

Programming Features:

- Intuitive Programming System (IPS) for conversational programming

- Visual Quick Code for common operations

- Wireless probing interface standard

- USB and Ethernet connectivity

- Advanced machining packages available

Operator Experience

Most machinists can learn how to use a Haas VF-2 well in just a few days. The control system on the Haas works like a normal CNC system without adding extra steps. It’s easy to set up, and the machine gives clear feedback about cutting conditions and possible problems.

Mazak VTC-200: Advanced Capabilities

Mazak Control System

The Mazak Matrix control has advanced programming features that are made for machining complex parts quickly. Automatic cutting performance optimization is done by SmoothG interpolation, advanced look-ahead, and smart feed rate control.

Programming Features:

- Advanced SmoothG toolpath optimization

- Intelligent feed rate control

- 3D surface machining capabilities

- Integrated part programming

- Advanced probing cycles

- Network connectivity and data collection

Operator Experience

The Mazak takes longer to learn, but skilled operators get better performance from it. Once the operators learn the advanced features, programming complicated parts is easier, but it takes longer to learn than the Haas.

Support Network and Service: When Things Go Wrong

The long-term satisfaction of a machine is often more important than its initial performance specifications.

Haas VF-2 Support

Service Network

Haas has the largest service network in North America, with more than 300 authorized dealers and service centers. Most big cities have parts available the same day and service available the next day.

Parts Availability

Haas keeps a large stock of parts on hand, so most of the most common ones can be shipped right away. There are no hidden markups or surprise costs when it comes to parts pricing; it’s clear and the same at all dealers.

Technical Support

24/7 phone support puts you in touch with Haas technical experts who can diagnose problems from afar and help with repairs. The quality of support is always great throughout the whole network.

Training and Documentation

Haas offers full training programs, detailed manuals, and a lot of online resources. The documentation is clear and useful, and it focuses on helping operators and maintenance workers fix real problems. – See: https://www.haascnc.com/owners/Service/operators-manual.html#gsc.tab=0

Mazak VTC-200 Support

Service Network

Mazak has about 80 service centers in North America, mostly in areas where a lot of manufacturing happens. The quality of service is usually very good, but the coverage is not as wide as Haas’s.

Parts Availability

Parts for current production machines are easy to find, but it may take longer to get parts for older models. Prices can be different at different dealers, and some parts cost a lot more than Haas parts.

Technical Support

Mazak’s technical support is very knowledgeable, but you may need to make an appointment instead of being able to call right away. Most service technicians have had a lot of training and can do complicated diagnostic work.

Training and Documentation

Mazak has great training programs, but they cost more than Haas’s. The documentation is complete but can be hard to understand because the machine is so advanced. See: https://www.mazak.com/jp-en/technology/mazatrol-cnc/

Cost Analysis

To get a full picture of the machine’s economics, you need to look at the purchase price, operating costs, maintenance costs, and resale value over the machine’s useful life.

Purchase Price Comparison (Used Market)

Haas VF-2 Pricing (2015-2020 models):

- 2015-2016: $45,000-$55,000

- 2017-2018: $55,000-$65,000

- 2019-2020: $65,000-$75,000

Mazak VTC-200 Pricing (2015-2020 models):

- 2015-2016: $50,000-$65,000

- 2017-2018: $60,000-$75,000

- 2019-2020: $70,000-$85,000

Note: In the used market, the Mazak usually costs $5,000 to $10,000 more than similar Haas machines. This is because it is a high-end machine with advanced features.

Operating Cost Analysis

Power Consumption

The power needs and usage patterns of both machines are similar. The Mazak’s faster spindle speeds can use more power while cutting, but for most shops, the difference is usually less than $500 a year.

Tooling Costs

Because the Mazak’s spindles spin faster, it can use smaller, cheaper cutting tools for many jobs. But the advanced spindle also needs better tool holders to work at their best, which could make tooling costs go up.

Programming Time

Given that their control system is simple, Haas machines usually take less time to program simple parts. Mazak machines have advanced features that can cut down on programming time for complicated parts, but they need more experienced programmers.

Maintenance Cost Comparison

Routine Maintenance

Both machines need the same kinds of regular maintenance and cost the same amount. Mazak machines may cost a little more to maintain because they have more complicated systems and need special service.

Major Repairs: Spindle Rebuilds

It usually costs between $18,000 and $25,000 to rebuild a Haas VF-2 spindle. Because the high-speed spindle design is more complicated, Mazak VTC-200 rebuilds cost between $22,000 and $30,000.

Ball Screw Replacement

Costs are about the same for both machines, usually between $8,000 and $15,000 per axis, depending on size and complexity.

Control System Issues

Haas repairs are often cheaper because there are more parts available and more service technicians who know how to work on the system.

Resale Value Analysis

Haas VF-2 Resale Performance

After five years, Haas machines are worth 60–65% of what they cost. After ten years, they are worth 45–50% of what they cost. There is a lot of demand for this CNC mill and it is widely accepted in the market.

Mazak VTC-200 Resale Performance

After five years, Mazak machines usually keep 50–55% of their original price, and after ten years, they keep 35–40%. Lower resale values are due to the fact that there aren’t as many people looking to buy used high-performance equipment and new machines cost more.

Total Cost Impact

The Haas VF-2 has a better resale value than the Mazak, which means that the total cost of ownership is about the same even though the purchase prices are different.

Real-World Application Analysis

Knowing how these machines work in different manufacturing settings can help you figure out how well they will work in your own situation.

Job Shop Environment

Haas VF-2 Advantages:

- Simple programming reduces setup time for varied work

- Reliable operation minimizes downtime between jobs

- Easy operator training allows flexible staffing

- Strong support network ensures quick problem resolution

- Excellent resale value protects investment

Best Applications: General machining, making prototypes, small to medium production runs, and shops with workers of all skill levels.

Mazak VTC-200 Advantages:

- Higher speeds reduce cycle times on complex parts

- Advanced programming features handle difficult geometry

- Superior accuracy improves part quality and reduces scrap

- Higher spindle speeds optimize small tool performance

Best Applications: Shops with skilled programmers and operators, complex aluminum parts, and high-precision work.

Production Environment

Haas VF-2 Advantages:

- Proven reliability in continuous operation

- Simple maintenance procedures reduce downtime

- Consistent performance across shifts and operators

- Lower training requirements for production staff

Mazak VTC-200 Advantages:

- Faster cycle times improve throughput

- Advanced features optimize cutting parameters automatically

- Better surface finishes may eliminate secondary operations

- Higher accuracy reduces quality issues

Specific Industry Applications

Aerospace Components

The Mazak VTC-200 is usually the best choice for aerospace work because it is more precise, has better programming options, and can make better surface finishes on crucial components.

General Manufacturing

The Haas VF-2 is usually better for general manufacturing because it is simple, reliable, and has a lower total cost of ownership for most parts and volumes.

Mold and Die Work

Both machines do a good job with mold work, but which one you choose depends on how complicated the work is and how skilled the programmer is.

The Honest Verdict: Choosing the Right Machine

After testing thousands of both machines over 37 years, this is our honest opinion on when each one is the best choice.

Choose the Haas VF-2 If:

- Support and Service Matter Most: If you need parts right away, a wide service network, and technical support around the clock, the Haas advantage is too great to ignore. Most stores are only 2 to 4 hours away from a Haas service center.

- Simplicity is Important: The Haas control system is great for training time and daily productivity if you have operators with different skill levels or prefer simple programming and operation.

- Resale Value is a Priority: The Haas’s higher resale value gives you a lot of financial protection if you plan to upgrade or change equipment in the next 5 to 7 years.

- Budget is Constrained: If purchase price and total cost of ownership are primary concerns, the Haas typically provides better value through lower acquisition costs and superior resale values.

- General Machining Focus: The Haas is a great choice for job shops because it can handle a wide range of materials, part sizes, and levels of difficulty.

Choose the Mazak VTC-200 If:

Speed and Precision Are Critical: If cutting down on cycle time and improving accuracy directly affect your bottom line, the Mazak’s performance benefits make the extra money worth it.

Aluminum Work Dominates: If you make mostly aluminum parts, the Mazak’s high-speed spindle can help you get a lot more work done.

You Have Skilled Operators: The Mazak’s advanced features give you an edge over your competitors if your programmers and operators can use them well.

Complex Parts Are Common: The Mazak’s advanced control system is very helpful if you often work with complex 3D shapes, tight tolerances, or materials that are hard to machine.

Production Efficiency Matters Most: If your main goals are to maximize throughput and minimize cycle times, the Mazak’s speed advantages often make it worth the extra money to run it.

The Controversial Take

A lot of shops chose the Mazak for the wrong reasons, but the Haas VF-2 would be a better fit for most of them. This is something that equipment sellers won’t tell you.

When it comes to specific job types, like working with aluminum, demanding precision, or dealing with complex geometries, the Mazak VTC-200 truly becomes the better CNC mill. However, the purchase, operation, and maintenance costs are higher. The alluring features entice many stores, but they fail to evaluate whether or not they will make good use of the sophisticated features.

Machinists who mistakenly believe that complexity equals quality unfairly criticize the Haas VF-2. Actually, Haas made CNC operations easier so that companies could concentrate on producing components rather than micromanaging machines. Thanks to its superior reliability, service, and total cost of ownership, Haas offers greater value to 80% of American manufacturing.

Recommendations by Shop Type

Small Job Shops (1-10 Employees)

Haas VF-2: For smaller businesses that cannot afford prolonged downtime or intricate troubleshooting, the Haas is the safer option due to its support network, ease of use, and protection of resale value.

Medium Production Shops (10-50 Employees)

Depending on the application, the Mazak works well in shops with knowledgeable employees and workloads involving a lot of aluminum. The Haas usually work better in shops with a variety of tasks and a range of skill levels.

Large Manufacturing Operations (50+ Employees)

Mazak VTC-200: Big businesses can successfully leverage the performance benefits and justify the training investment. Improvements in cycle time frequently yield a rapid return on the extra investment.

Startup Operations

Haas VF-2: For new machine shops and research and development departments, reliability and support are more important than performance. The Haas is a safer way to set up operations and develop new products.

High-Volume Production

Mazak VTC-200: When cycle time has a direct effect on profits, the Mazak’s speed benefits make the extra work and cost worth it.

Conclusion: Making the Right Choice

The Haas VF-2 and Mazak VTC-200 are both great machines that are popular because they work well in thousands of shops around the world. Instead of vague ideas about which one is “better,” you should choose between them based on your own needs, abilities, and priorities.

The Haas VF-2 is the best example of American manufacturing pragmatism: it’s reliable, well-supported, and made for real-world production settings. It’s like the Toyota Camry of CNC machines: not the most exciting choice, but one that always gives you good value.

The Mazak VTC-200 is a great example of Japanese precision engineering. It’s fast, accurate, and can do amazing things in the right hands. It has amazing features that reward skilled use but cost more and require more knowledge to use.

Your choice should be based on what your shop can do, how much work it has, and what its long-term goals are. If a shop can’t use a Mazak VTC-200 to its full potential, it becomes an expensive Haas VF-2. On the other hand, a Haas VF-2 in a shop that needs the Mazak’s speed and accuracy slows down productivity.

For 37 years, we’ve helped thousands of manufacturers at Premier Equipment make this choice. The best machine for your shop is not always the one with the best specs or the one that your friends are most likely to buy. It is the one that meets your needs, capabilities, and budget.

Whether you go with Haas or Mazak, make sure to look for a well-kept model with full maintenance records and a price that makes sense. When chosen, maintained, and used correctly, both machines can last for decades without breaking down.

This analysis shows what Premier Equipment considers based on decades of experience in the industry. We don’t work for or get paid by any of the companies mentioned in this comparison. This means that our suggestions are only based on what is best for the customer and what will last for a long time.

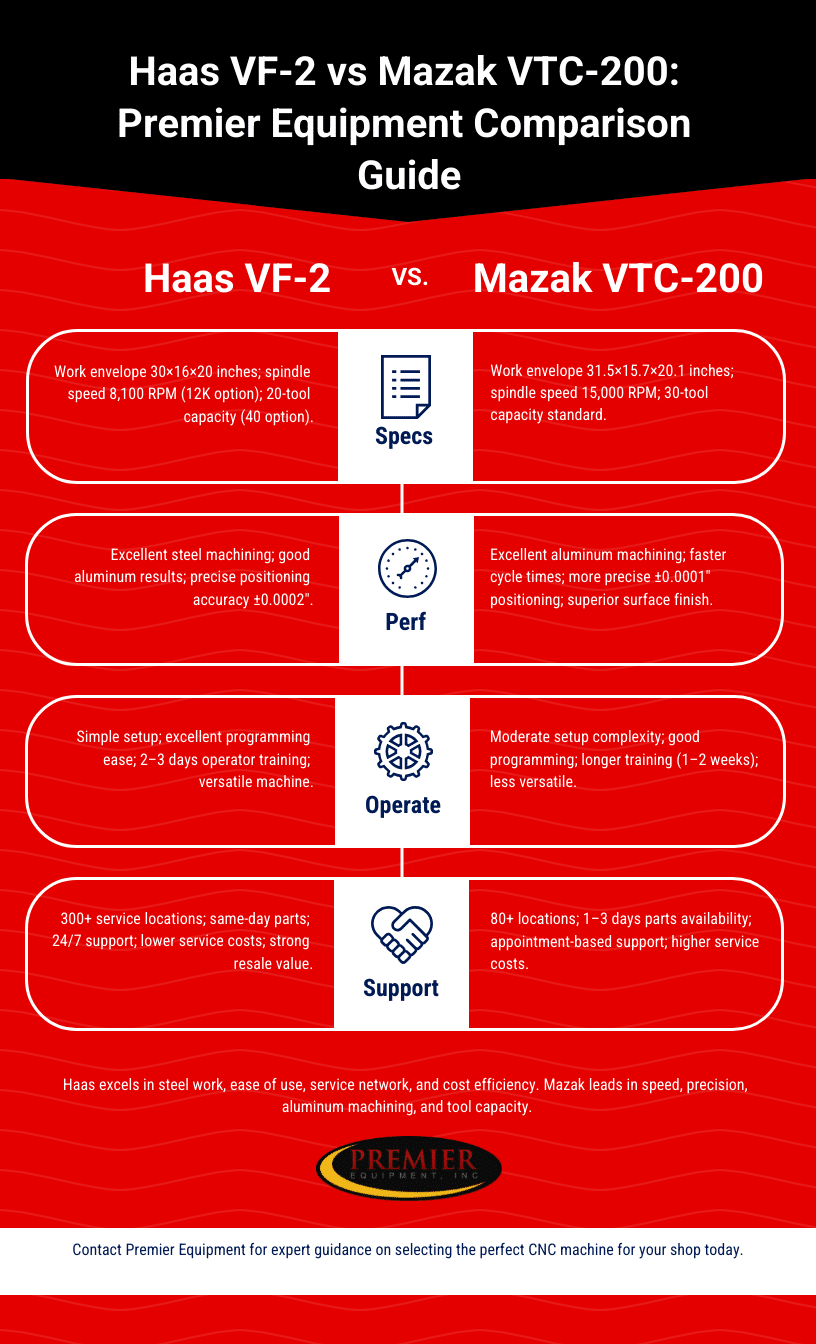

Infographic Comparison