For the oil and gas industry, one of the most complex and capital intensive industries there is, there is a perpetual quest to minimize costs and improve efficiency. Adopting used CNC machines is one strategy that is often overlooked but can have a huge impact on both bottom line savings as well as operational scalability. In this article, we explore how used CNC machines can be integrated into the oil and gas sector and the applications, benefits and strategic considerations.

The Need for Precision in the Oil and Gas Industry

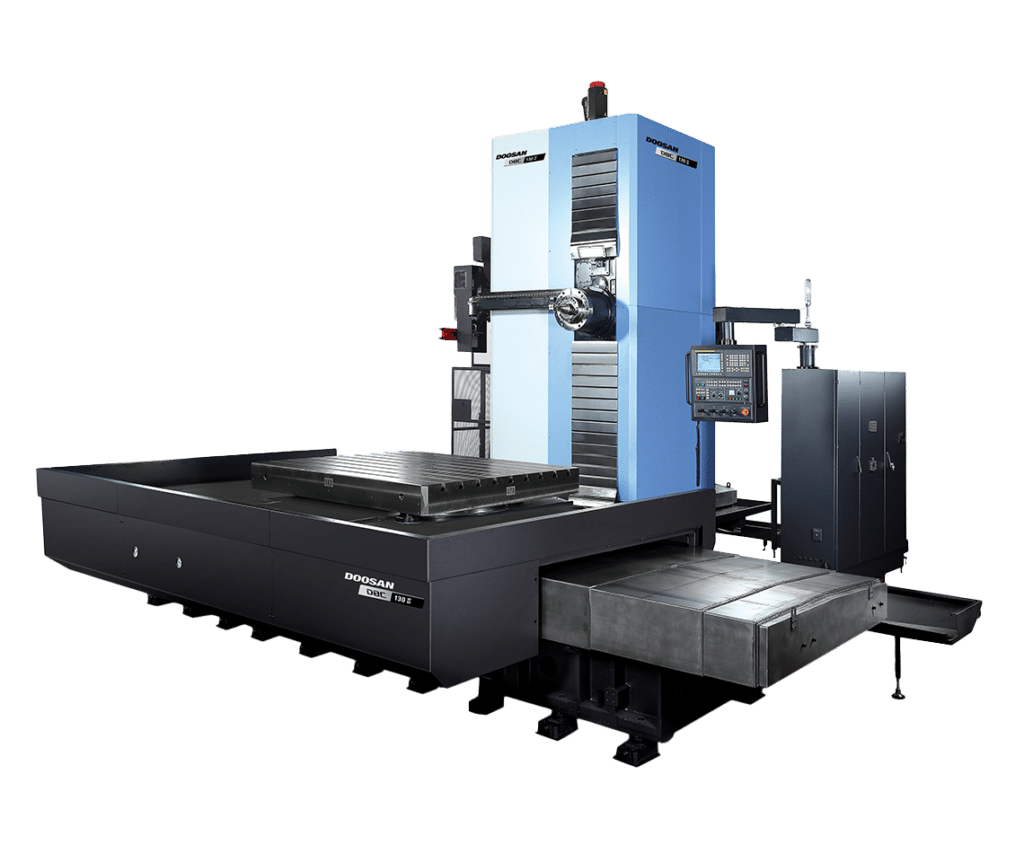

It is a precision and reliability driven industry. Every part, from the drilling equipment to the pipeline components, must meet rigorous standards to be safe, efficient and in compliance with required regulations. This level of precision can only be achieved with CNC machines, new or used.

For several reasons, used CNC machines, in particular, provide a compelling solution. First, they offer the same level of precision and accuracy as new machines, but for a fraction of the up front cost. For companies that want to grow their manufacturing capabilities but don’t want to pay the full price for new equipment, this cost savings can be significant.

In addition, used CNC machines are easy to integrate into the current workflows, minimizing downtime and providing for quick ramp up of production. In the oil and gas sector, delays can be very costly, and this is particularly important. For example, a drilling operation that needs to make custom parts can take advantage of used CNC machines being deployed quickly to make those parts, reducing lead times and keeping a project on schedule.

Cost Savings and Financial Benefits

The greatest advantage of used CNC machines in the oil and gas industry is the potential for substantial cost savings. CNC machines are expensive — often hundreds of thousands of dollars. On the other hand, used CNC machines can be purchased for a fraction of this price often even 20 30% of the original price.

The difference in cost can be life changing for companies with tight margins or those who want to allocate resources more efficiently. Investing in used CNC machines gives companies the opportunity to save and put it towards other areas of high importance such as research and development, workforce training, or even expand their product line.

Also, CNC machines tend to have good resale value, and after several years of usage, these machines could be sold at a reasonable resale value of what was prevalent when purchased. This makes them a smart long term investment, you can resell your used one to recoup some of the initial expenditure or trade it in for newer models when needed.

Scalability and Flexibility

Another main benefit of using used CNC machines with the oil and gas industry is scalability. In fact, companies should be able to scale their production capacity quickly as demand fluctuates. This flexibility comes at no hefty price at all because used CNC machines offer this.

For instance, when demand is high other online used CNC machines can be brought online to increase production capacity. On the flip side though, these machines can be sold or put out to lease to other companies when business is slower to help defer costs and fund the flow of cash.

Additionally, used CNC machines can be tailored to suit a particular need. Refurbished machines will have many of the worn parts replaced or new ones fitted and will be upgraded in terms of software and recalibrated to meet present day standards provided by many manufacturers. Such a high degree of customization enables companies to customize their equipment to exact measurements, which ultimately improves the overall efficiency of the equipment and resulting product quality.

Maintaining Quality and Reliability

One misconception regarding used CNC machine is that they are less reliable or made of low quality than new CNC machine. This is not necessarily true, however. There are many used CNC machines that are well cared for and regularly serviced for the entirety of their life.

If you are buying a used CNC machine, it is very important to deal with ethical CNC machine dealers that are able to provide detailed maintenance records, and/or warranties or guarantees. This way, we keep the machine working well and greatly reduce the risk of unexpected downtime.

In addition, CNC technology has improved to the point where older machines can easily be integrated into modern manufacturing systems. Older machines can be brought up to where they’ll seamlessly play with newer hardware and software updates or hardware updates.

Strategic Considerations for Buying and Selling

There are many strategic considerations which should be taken into account when companies are choosing to purchase used CNC machines. Before considering the machine, we must first know how the market demand of the machine being considered operates. In terms of this, you will research what the industry trends are and consult with peers to make sure the investment holds up in the years to come.

Second, well the machine before purchase must be inspected and tested thoroughly. Reviewing maintenance records, physical inspections, and test cycles are part of the mix to be sure the machine will work as expected.

However, for the companies that want to sell their used CNC machines, timing is everything. There are times when you can sell when the demand is high and you get a higher price, and times when you sell when the economy is down and you may not get as much. Also, for exactly the same reason, preparing the machine for sale through necessary maintenance and repairs can increase the machine resale value significantly.

Conclusion

Used CNC machines provide a great value to the oil and gas industry. These machines are a compelling solution for companies looking to save costs and financial benefits while getting full value for money, scalable systems that are flexible, and do not compromise quality or reliability.

The applications, benefits, and strategic considerations of purchasing and selling used CNC machines provide industry leaders with the information needed to make informed decisions that will increase efficiency, reduce costs, and ultimately increase competitiveness. With the manufacturing landscape changing, the oil and gas sector may find embracing the potential of used CNC machines a game changer.