Mazak Corporation is the undisputed world leader in CNC machine tools with the largest market share in the world with revenue of 5.28 billion dollars and more than a hundred years of manufacturing innovation. To the manufacturing professionals and CNC programmers, it is important to learn the complete machine code system of Mazak in order to optimize productivity and accuracy in the current machining processes.

Mazak’s revolutionary approach to CNC programming

The programming system at Mazak is a more advanced development of the old G-code systems. In 1981, the MAZATROL conversational programming system was the first conversational CNC programming interface in the world, enabling operators to program machines in normal language instead of complicated code structures. This two-mode system offers the ease of use of conversational programming and the accuracy of conventional EIA/ISO G-code, thus Mazak systems can be used by both skilled programmers and those who are new to CNC machining.

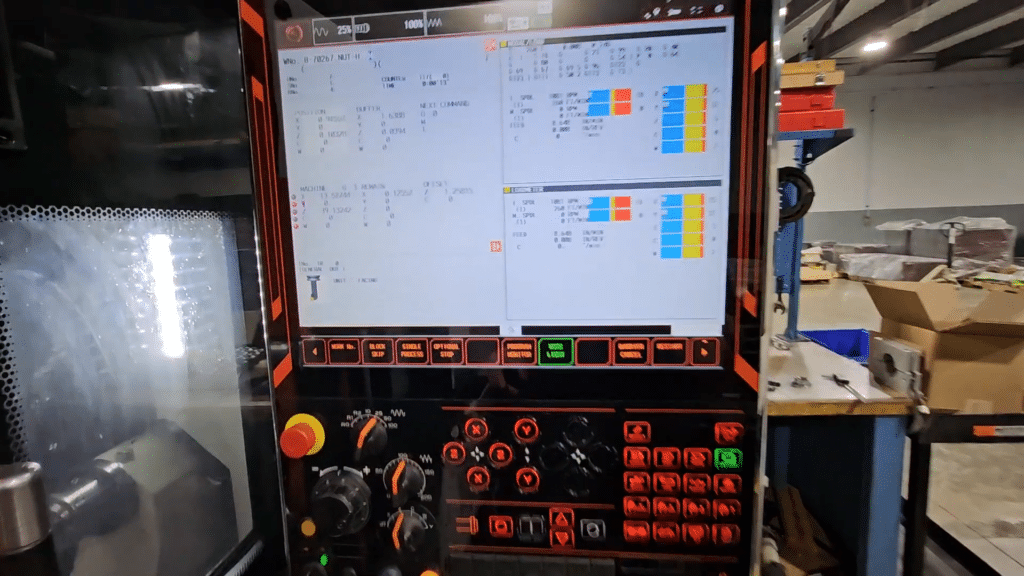

The new MAZATROL SmoothAi controllers in the company incorporate artificial intelligence that develops through the experience of programming and automatically optimizes machining processes and cutting conditions. This is a major improvement on the conventional programming techniques where AI is used to generate toolpaths, optimize processes, and predictive maintenance.

Complete Mazak machine code reference tables

Mazak G-codes for M-series machining centers

| G-Code | Description | Application |

|---|---|---|

| G00 | Rapid positioning | Fast non-cutting moves |

| G01 | Linear interpolation | Straight cutting moves |

| G02 | Circular interpolation CW | Clockwise arcs and circles |

| G03 | Circular interpolation CCW | Counterclockwise arcs and circles |

| G02.1 | Spiral interpolation CW | Clockwise helical cutting |

| G03.1 | Spiral interpolation CCW | Counterclockwise helical cutting |

| G04 | Dwell/pause | Temporary stop with timer |

| G05 | High-speed machining mode | Optimized acceleration profiles |

| G06.1 | Fine spline interpolation | Smooth surface finishing |

| G06.2 | NURBS interpolation | Complex surface finishing |

| G07.1 | Cylindrical interpolation | Specialized cylinder operations |

| G09 | Exact stop check | Precise positioning verification |

| G10 | Programmable data input | Work offset and tool setting |

| G11 | Programmable data input cancel | Cancel G10 mode |

| G17 | XY plane selection | Circular interpolation in XY |

| G18 | ZX plane selection | Circular interpolation in ZX |

| G19 | YZ plane selection | Circular interpolation in YZ |

| G20 | Inch programming | Imperial units |

| G21 | Metric programming | Millimeter units |

| G28 | Return to reference point | Machine zero return |

| G29 | Return from reference point | Move from machine zero |

| G40 | Tool radius compensation cancel | Cancel cutter compensation |

| G41 | Tool radius compensation left | Left-side cutter compensation |

| G42 | Tool radius compensation right | Right-side cutter compensation |

| G43 | Tool length compensation positive | Positive tool length offset |

| G44 | Tool length compensation negative | Negative tool length offset |

| G49 | Tool length compensation cancel | Cancel tool length offset |

| G53 | Machine coordinate system | Absolute machine positioning |

| G53.5 | MAZATROL coordinate system | Program-resident work offsets |

| G54-G59 | Work coordinate systems | Six standard work offsets |

| G80 | Fixed cycle cancel | Cancel all fixed cycles |

| G81 | Drilling cycle | Standard hole drilling |

| G82 | Drilling cycle with dwell | Drilling with pause |

| G83 | Peck drilling cycle | Deep hole drilling |

| G84 | Tapping cycle | Threading operations |

| G85 | Boring cycle | Precise hole boring |

| G86 | Boring cycle with stop | Boring with spindle stop |

| G87 | Back boring cycle | Reverse boring operations |

| G88 | Boring cycle with manual | Manual boring operations |

| G89 | Boring cycle with dwell | Boring with pause |

| G90 | Absolute programming | Absolute coordinate mode |

| G91 | Incremental programming | Incremental coordinate mode |

| G92 | Coordinate system setting | Local coordinate establishment |

| G94 | Feed per minute | mm/min or in/min feed rate |

| G95 | Feed per revolution | mm/rev or in/rev feed rate |

| G96 | Constant surface speed | CSS for turning operations |

| G97 | Constant spindle speed | RPM mode |

| G98 | Return to initial point | Fixed cycle return level |

| G99 | Return to R point | Fixed cycle intermediate return |

| G130 | Tornado cycle | High-speed roughing cycle |

| G136 | Measurement cycle | Workpiece measurement |

| G137 | Tool measurement | Tool setting and verification |

Mazak G-codes for T-series turning centers

| G-Code | Description | Application |

|---|---|---|

| G00 | Rapid positioning | Fast non-cutting moves |

| G01 | Linear interpolation | Straight cutting moves |

| G02 | Circular interpolation CW | Clockwise arcs |

| G03 | Circular interpolation CCW | Counterclockwise arcs |

| G04 | Dwell | Pause with timer |

| G20 | Inch programming | Imperial units |

| G21 | Metric programming | Millimeter units |

| G28 | Reference point return | Machine zero return |

| G32 | Thread cutting | Straight and taper threads |

| G40 | Tool nose radius compensation cancel | Cancel TNRC |

| G41 | Tool nose radius compensation left | Left TNRC |

| G42 | Tool nose radius compensation right | Right TNRC |

| G50 | Coordinate system/max speed | Work offset and speed limit |

| G70 | Finishing cycle | Precision finishing operations |

| G71 | Longitudinal roughing | Parallel roughing cycle |

| G72 | Transverse roughing | Face roughing cycle |

| G73 | Contour parallel roughing | Pattern roughing cycle |

| G74 | End face peck drilling | Axial drilling operations |

| G75 | Grooving cycle | Longitudinal grooving |

| G76 | Threading cycle | Complete threading operations |

| G90 | Longitudinal turning cycle | Simple turning operations |

| G92 | Threading cycle | Basic threading |

| G94 | Transverse turning cycle | Face turning operations |

| G96 | Constant surface speed | CSS mode |

| G97 | Constant spindle speed | RPM mode |

| G122 | Polar coordinate programming | Complex coordinate systems |

| G123 | Polar coordinate cancel | Exit polar mode |

Complete Mazak M-code reference

| M-Code | Description | Machine Type |

|---|---|---|

| M00 | Program stop | All machines |

| M01 | Optional stop | All machines |

| M02 | Program end | All machines |

| M03 | Spindle start CW | All machines |

| M04 | Spindle start CCW | All machines |

| M05 | Spindle stop | All machines |

| M06 | Tool change | Machining centers |

| M07 | Mist coolant on | All machines |

| M08 | Flood coolant on | All machines |

| M09 | Coolant off | All machines |

| M19 | Spindle orientation | All machines |

| M20 | Robot arm advance | With automation |

| M21 | Robot arm retract | With automation |

| M22 | Robot clamp | With automation |

| M23 | Robot unclamp | With automation |

| M30 | Program end and reset | All machines |

| M33 | Chuck pressure high | Turning centers |

| M34 | Chuck pressure low | Turning centers |

| M41 | Low gear range | All machines |

| M42 | High gear range | All machines |

| M72 | Inside chuck clamp | Turning centers |

| M73 | Outside chuck clamp | Turning centers |

| M81 | Workpiece measurement | With probing |

| M82 | Tool measurement X | With probing |

| M83 | Tool measurement Z | With probing |

| M84 | Tool measurement XZ | With probing |

| M100 | Measurement output | With probing |

| M110 | Measurement comparison | With probing |

| M120 | Measurement data save | With probing |

| M153 | Milling spindle through coolant | INTEGREX series |

| M154 | Mill spindle through coolant off | INTEGREX series |

| M155 | Chuck coolant on | Turning centers |

| M156 | Chuck coolant off | Turning centers |

| M169 | High pressure coolant | With HPC system |

| M200 | Turning spindle CW | INTEGREX series |

| M201 | Turning spindle CCW | INTEGREX series |

| M202 | Turning spindle stop | INTEGREX series |

| M203 | Turning spindle orientation | INTEGREX series |

| M204 | C-axis unclamp | INTEGREX series |

| M205 | C-axis clamp | INTEGREX series |

| M300 | Second spindle CW | Twin spindle machines |

| M301 | Second spindle CCW | Twin spindle machines |

| M302 | Second spindle stop | Twin spindle machines |

| M303 | Second spindle orientation | Twin spindle machines |

| M310 | Spindle synchronization on | Twin spindle machines |

| M311 | Spindle synchronization off | Twin spindle machines |

| M319 | Second spindle position | Twin spindle machines |

| M511 | Synchronized spindle rotation | INTEGREX series |

| M512 | Synchronized spindle stop | INTEGREX series |

| M513 | Synchronized spindle cancel | INTEGREX series |

MAZATROL-specific programming codes

| Function | Code/Command | Description |

|---|---|---|

| Unit Selection | IN/MM | Imperial or metric units |

| Tool Call | T## | Tool selection and offset |

| Work Offset | #1-#6 | MAZATROL work coordinate systems |

| Face Mill | FACE | Conversational face milling |

| Profile Mill | PROFILE | Conversational profile milling |

| Pocket Mill | Conversational pocket milling | |

| Drilling | DRILL | Conversational drilling cycle |

| Boring | BORE | Conversational boring cycle |

| Tapping | TAP | Conversational tapping cycle |

| Turn/Face | TURN/FACE | Turning operations |

| Thread Cut | THREAD | Threading operations |

| Groove | GROOVE | Grooving operations |

| Part Off | PART | Parting operations |

| Polygon Turn | POLYGON | Multi-sided turning |

Advanced Mazak controller features

| Feature | Function | Benefit |

|---|---|---|

| Variable Feed Control (VFC) | Real-time feed optimization | Improved surface finish |

| Tool Path Store (TPS) | Program interruption/continuation | Safe program restart |

| Smooth Corner Control | Corner smoothing algorithm | Reduced cycle time |

| Look-Ahead Processing | Unlimited block preview | Optimized acceleration |

| MAZATROL Preview | Graphical program verification | Error prevention |

| Auto Power Save | Automatic power management | Energy efficiency |

| Collision Avoidance | Real-time interference checking | Machine protection |

| Tool Life Management | Automatic tool monitoring | Predictive maintenance |

This extensive code reference shows how Mazak has developed a highly advanced method of CNC programming, with compatibility to ISO standards, but with proprietary extensions that provide high performance and productivity in contemporary manufacturing facilities.

Programming best practices and real-world applications

To program Mazak successfully, one must know conversational and G-code programming. MAZATROL conversational programming is well suited to job shop applications that require fast changeover of setups and a variety of part requirements that require a flexible programming method. Automatic calculation of intersection coordinates and toolpath optimization capabilities of the system make it a perfect choice in case the operator has to concentrate on machining rather than on the complexity of the programming.

G-code programming is necessary when geometries are complex, when toolpaths are generated by CAM, and when it is necessary to have fine control over the toolpath. The dual-mode programming feature enables the programmer to switch between conversational and G-code programming in the same program and offers the greatest flexibility to meet the varying machining needs.

Such advanced functions as the Variable Feed Control (VFC) allow optimizing feeds and speeds in real-time during the cutting process, whereas the Tool Path Store (TPS) feature makes it possible to pause the program and resume it safely. These characteristics in conjunction with the Mazak Smooth Corner Control and unlimited look-ahead processing provide excellent surface finishes and shorter cycles.

Comparison with standard implementations

The strategy of Mazak is to balance the requirements of ISO 6983 and proprietary improvements. Mazak brings a lot of value to the standard G-code functionality with conversational programming, advanced work offset management, and integrated manufacturing capabilities, all of which remain compatible with standard G-code functionality. G53.5 MAZATROL coordinate system avoids work offset conflicts because it keeps program-resident coordinates, which is a frequent cause of machining errors.

The main departure of the standard implementations is machine-specific M-codes, which are highly customized to the capabilities of Mazak hardware. The extent of Mazak integrated approach to manufacturing automation is evidenced by the robot integration codes (M20-M29), multi-spindle coordination functions and complex measurement cycles.

Compatibility with CAM software is also good, with the majority of the major systems offering Mazak-specific post-processors. Mazatrol programs are however not directly transferable to other CNC systems and long term programming strategy and operator training needs must be considered.

Essential considerations for implementation

The most important benefit to manufacturing professionals who are considering Mazak systems is the flexibility in programming that can be used to suit varying levels of skills and application needs. The conversational programming interface cuts down the time needed to train new operators, but still has full G-code capability to support complex applications.

The quickest route to productivity is through investment in official Mazak training programs, with more than 100 courses offered in the National Technology Center and online MODL platform.

The programming strategy must take advantage of the conversational and G-code capabilities instead of imposing the traditional methods on the MAZATROL system. To succeed, one should realize that the philosophy of Mazak is to describe part geometry instead of defining tool paths, so the system can optimize cutting processes automatically.

The total combination of measurement, automation, and process optimization in Mazak systems offers high competitive advantages in the contemporary manufacturing world. The advanced programming features of the system usually allow companies applying Mazak technology to attain better quality consistency, shorter setup times, and greater flexibility in production.

The fact that Mazak is the world leader in CNC machine tools and has a revolutionary approach to programming and constant technological development makes the knowledge of these machine codes a necessity to manufacturing professionals. The competitive advantage of the company in the contemporary precision manufacturing is based on the dual-mode programming system, advanced controller functions, and extensive automation possibilities.