Mazak Variaxis 500 vs 630: 5-Axis CNC Machine Comparison

A guide to choosing between Mazak’s most popular 5-axis machining centers for complex manufacturing

Last month, Mike, who owns a machine shop in Ohio with 25 employees, called us because he was having to make the most significant equipment decision of his professional life. He was ready to invest in his first 5-axis CNC machine after years of turning down high-end aerospace projects due to his inability to handle the multi-axis requirements. He couldn’t decide between a used Mazak Variaxis 500 (AVG $240,000) and a Variaxis 630 (AVG $390,000).

Mike told us, “If I can handle 5-axis parts, I have three customers ready to give me $2 million in work.” “However, I’m afraid that we’ll spend our whole equipment budget on a machine that’s either too complicated for my guys to operate or too small for the job.”

We have 37 years of experience helping manufacturers like Mike’s make these crucial decisions, and we have witnessed both brilliant and disastrous executions of this choice. Two different strategies for introducing 5-axis manufacturing are demonstrated by the Mazak Variaxis 500 and Variaxis 630: job shop efficiency versus production power, and manageable complexity versus maximal capabilities.

Overnight, both machine tools have the potential to drastically alter a shop’s capabilities. They open up sectors that need 5-axis precision, enable complex products at premium prices, and eliminate a number of setups that lower profitability. They are investments that, if poorly selected, may strain the operating and financial resources of small businesses.

Let’s explore both machines, including long-term growth prospects, overall investment costs, programming realities, and work envelope requirements. Our goal is to help you choose the tools that will improve your abilities without breaking the bank or overtaxing your workforce.

Technical Specifications: Engineering Excellence Compared

To understand how these two Mazak models are different, you need to look at both their basic specs and how they work for making complicated parts.

Mazak Variaxis 500 Specifications

Work Envelope:

- X-Axis Travel: 20.08 inches (510mm)

- Y-Axis Travel: 15.75 inches (400mm)

- Z-Axis Travel: 15.75 inches (400mm)

- Table Size: 19.69″ diameter (500mm)

- Maximum Table Load: 661 lbs (300kg)

Rotary Axis Capabilities:

- A-Axis Range: +30° to -120°

- C-Axis Range: 360° continuous

- A-Axis Positioning: 0.001°

- C-Axis Positioning: 0.001°

- Simultaneous 5-Axis: Yes

Performance Specifications:

- Spindle Power: 22 HP (16.5 kW)

- Spindle Speed: 12,000 RPM

- Rapid Traverse: 1,574 IPM (40 m/min)

- Tool Capacity: 30 positions standard

- Tool Change Time: 2.7 seconds (chip to chip)

Machine Specifications:

- Machine Weight: 13,228 lbs (6,000kg)

- Floor Space: 118″ x 126″ x 98″ (H)

- Power Requirements: 400V, 3-phase, 50/60 Hz

Mazak Variaxis 630 Specifications

Work Envelope:

- X-Axis Travel: 24.80 inches (630mm)

- Y-Axis Travel: 21.65 inches (550mm)

- Z-Axis Travel: 20.08 inches (510mm)

- Table Size: 24.80″ diameter (630mm)

- Maximum Table Load: 1,323 lbs (600kg)

Rotary Axis Capabilities:

- A-Axis Range: +30° to -120°

- C-Axis Range: 360° continuous

- A-Axis Positioning: 0.0001°

- C-Axis Positioning: 0.0001°

- Simultaneous 5-Axis: Yes

Performance Specifications:

- Spindle Power: 30 HP (22 kW)

- Spindle Speed: 12,000 RPM

- Rapid Traverse: 1,574 IPM (40 m/min)

- Tool Capacity: 60 positions standard

- Tool Change Time: 2.7 seconds (chip to chip)

Machine Specifications:

- Machine Weight: 19,841 lbs (9,000kg)

- Floor Space: 142″ x 150″ x 106″ (H)

- Power Requirements: 400V, 3-phase, 50/60 Hz

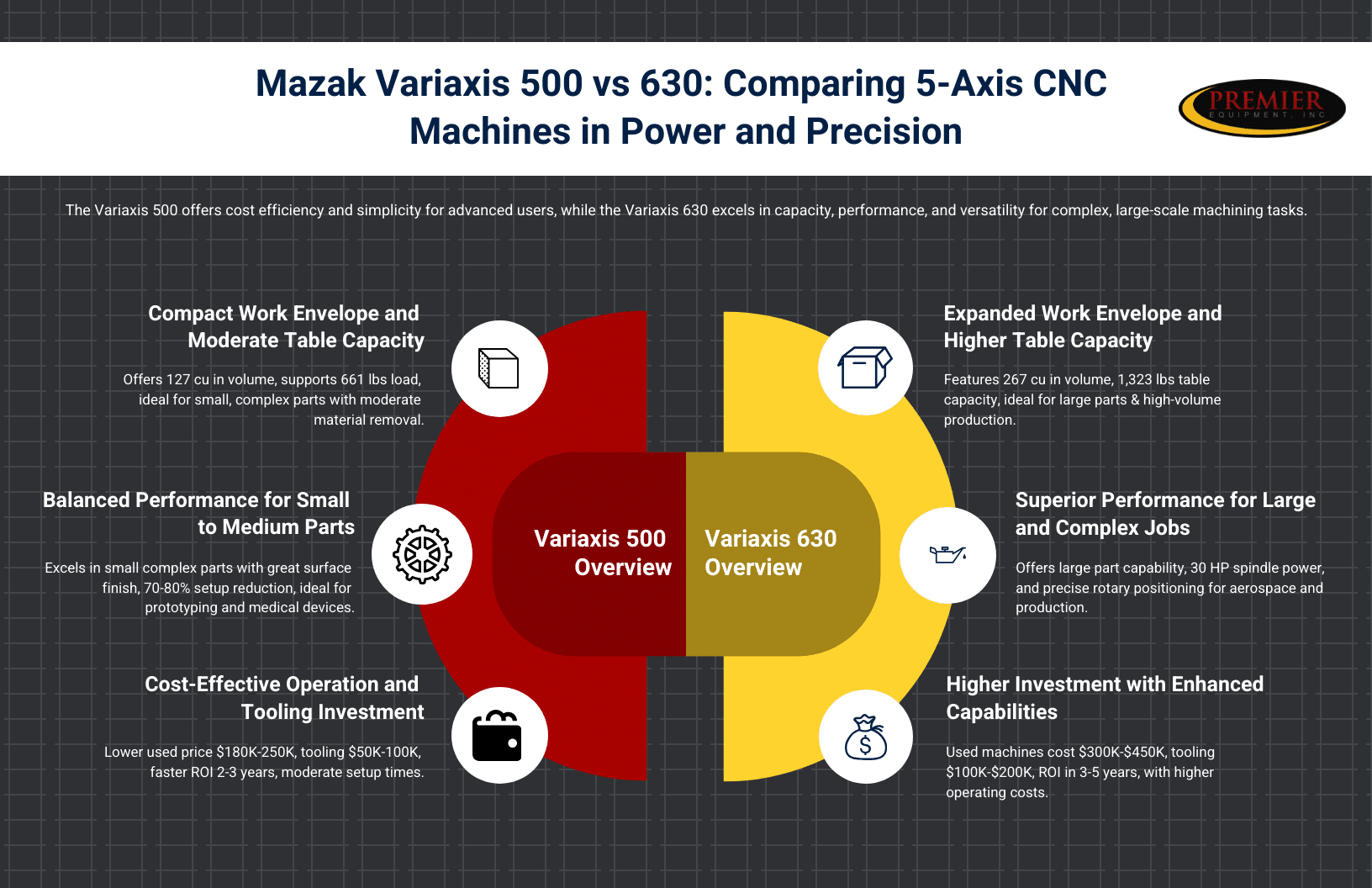

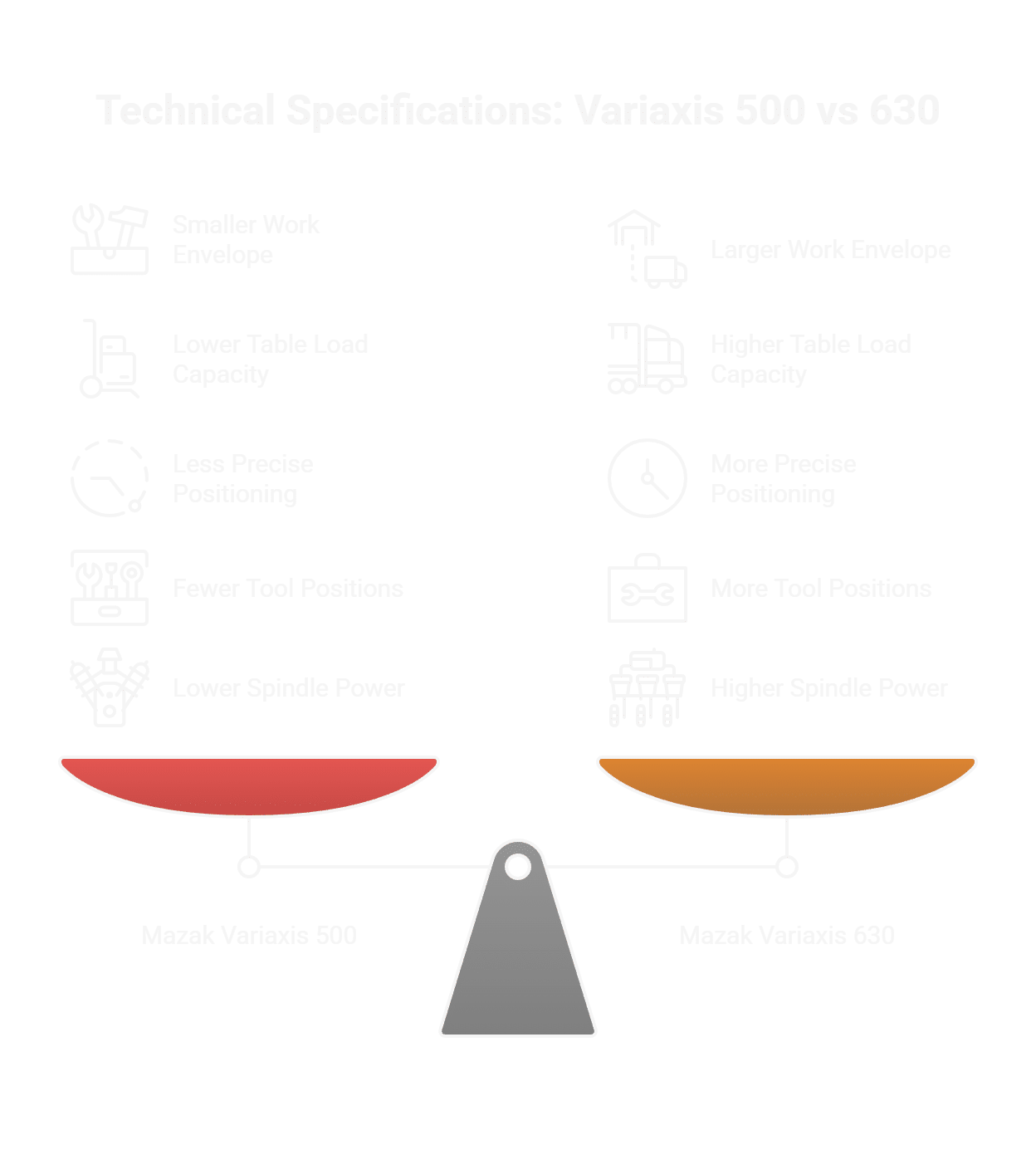

Specification Analysis

The numbers show that there are basic differences in design philosophy. The Variaxis 630 has 23% more movement on the X-axis, 37% more movement on the Y-axis, and 27% more movement on the Z-axis. This greatly increases the capabilities of the components. With a bigger table and four times the weight capacity, you can do a lot of various types of work.

More importantly, the 630’s better rotary axis placement (0.0001° vs 0.001°) and bigger tool capacity (60 vs 30 tools) make it perfect for complex, multi-operation items that the smaller machine would have trouble with. With 36% more spindle power (30HP instead of 22HP), it can cut through tougher materials.

Head-to-Head Comparison Table

| Comparison Factor | Variaxis 500 | Variaxis 630 | Winner |

|---|---|---|---|

| SPECIFICATIONS | |||

| Work Envelope Volume | 127 cubic inches | 267 cubic inches | 630 |

| Table Capacity | 661 lbs | 1,323 lbs | 630 |

| Spindle Power | 22 HP | 30 HP | 630 |

| Tool Capacity | 30 positions | 60 positions | 630 |

| Rotary Positioning | 0.001° | 0.0001° | 630 |

| PERFORMANCE | |||

| Small Complex Parts | Excellent | Excellent | Tie |

| Large Part Capability | Limited | Excellent | 630 |

| Material Removal Rate | Good | Excellent | 630 |

| Surface Finish | Excellent | Excellent | Tie |

| Setup Reduction | 70-80% | 80-90% | 630 |

| OPERATION | |||

| Programming Complexity | Moderate | High | 500 |

| Operator Skill Required | Advanced | Expert | 500 |

| Setup Time | Moderate | Extended | 500 |

| Versatility | Good | Excellent | 630 |

| FINANCIAL | |||

| Used Price (2018-2020) | $180K-250K | $300K-450K | 500 |

| Operating Costs | Lower | Higher | 500 |

| Tooling Investment | $50K-100K | $100K-200K | 500 |

| ROI Timeline | 2-3 years | 3-5 years | 500 |

| APPLICATIONS | |||

| Job Shop Work | ★★★★★ | ★★★☆☆ | 500 |

| Production Work | ★★★☆☆ | ★★★★★ | 630 |

| Aerospace Parts | ★★★★☆ | ★★★★★ | 630 |

| Medical Devices | ★★★★★ | ★★★★☆ | 500 |

| Prototyping | ★★★★★ | ★★★☆☆ | 500 |

| High-Volume Parts | ★★☆☆☆ | ★★★★★ | 630 |

Score Summary

- Variaxis 500 Wins: 7 categories (Cost, Simplicity, ROI)

- Variaxis 630 Wins: 9 categories (Capability, Performance, Capacity)

- Ties: 2 categories (Small parts, Surface finish)

The Bottom Line

The Variaxis 500 is great for stores that are just starting to use 5-axis production or that work with smaller, more complicated items. The Variaxis 630 is the clear winner when it comes to part size, manufacturing volume, or ultimate capacity. The number of parts needed and how complicated the operation is will help you make your decision.

Performance Analysis: Where Capability Meets Reality

5-axis machining’s performance goes far beyond what is required, including the ability to work with complex parts, strong materials, and flexible production that make these big investments worth it.

Part Complexity and Geometry Capabilities

Variaxis 500 Performance: The Variaxis 500’s small size makes it great for delicate parts that fit inside its body. The machine has a great rigidity-to-size ratio, which makes it useful for making complex aircraft brackets, medical implants, and precise mold parts. The 30-tool capacity makes it easy to do most 5-axis tasks, and the rotary placement accuracy lets well-programmed parts have feature errors of ±0.0002″.

Getting rid of setup and finding the best tool approach angles can usually cut cycle times by 60 to 80% compared to 3-axis operations. Parts that normally take 8–12 steps to make on standard machines can often be finished in just 2–3 setups, which greatly reduces handling mistakes and improves geometric relationships.

Variaxis 630 Performance: The Variaxis 630 can make parts that smaller machines can’t because it has a bigger area. The whole work area is great for big parts of aircraft structures, complicated mold sections, and systems that have been put together. With a 60-tool capacity, you can do full machining runs on complicated parts, and the better rotary placement lets you get close to ±0.00005″ accuracy on important features.

Setup time can be cut by 80 to 90% for large, complex parts. Parts that need 15 to 20 operations on 3-axis equipment can often be finished in one setup. This gets rid of tolerance stack-up and makes quality differences much smaller.

Material-Specific Performance

- Titanium Machining: Both machines can work with titanium, but the 630 has a stronger spindle (30HP vs. 22HP), so it can remove material faster. The bigger machine is stiffer, so it doesn’t bend as much when it cuts through heavy titanium. This makes the tools last longer and makes the finish look better.

- Aluminum Performance: Both tools work well with metal jobs. The 500 is lighter but still strong enough to cut through aluminum’s lower cutting forces. Both machines have spindles that spin at 12,000 RPM, which is the best speed for finishing aluminum.

- Steel and Iron: The 630’s power edge is clear in steel applications. The 630’s 30HP power makes it easy to do heavy roughing tasks that the 500’s 22HP spindle can’t handle. This cuts down on cycle times and makes tools last longer.

Programming and Operational Complexity

Programming and operating a 5-axis machine requires a lot more skill than running and writing code for a 3-axis machine. The machines are also very different in terms of how complicated they are and how many resources they need.

Programming Challenges and Solutions

Variaxis 500 Programming: It’s easier to find collisions and check tool paths with the 500 because it has a smaller footprint. Programming is still pretty hard, but people who know how to use CAM can do it. Most parts work well with 15 to 25 tools, which makes programming and setting up easier to handle.

Standard CAM packages do a good job of handling the machine’s kinematics, and big software companies offer well-known post-processors. Compared to 3-axis versions, programming time usually goes up by 200 to 300 percent. However, skilled coders can get good at it in 6 to 12 months.

Variaxis 630 Programming: Because the 630 has a bigger envelope and can hold 60 tools, programming it can be hard for teams that aren’t used to it. Because the reach and rotary area are bigger, collision recognition becomes very important. Parts that use the whole tool’s capacity need advanced tool control and change optimization.

Advanced CAM software tools are no longer just nice to have; they’re required. Programming often takes 400–500% longer than 3-axis work because it needs specific programming skills and a lot of simulation tools.

Operator Skill Requirements

Variaxis 500 Operation: The Variaxis 500 Operators need to know a lot about three axes and get six to twelve months of training in five axes. Setting up is hard but well-organized, and most workers get good at it in 12 to 18 months. With space for 30 tools, it’s easy for skilled users to keep track of their tools.

Variaxis 630 Operation: To run the Variaxis 630, you need workers who are very skilled and know a lot about 5-axis. If operators don’t get the right training and help, they can get too stressed out by complicated setups. It needs complicated systems and processes to keep track of all 60 tools it can hold. It usually takes 18 to 24 months for skilled workers to become fully proficient.

Cost Analysis: Investment Justification

In order to understand the comprehensive financial picture, it is necessary to analyze acquisition costs, operational expenses, fabrication investments, and productivity enhancements throughout the equipment lifecycle.

Acquisition Cost Comparison (Used Market)

Variaxis 500 Pricing (2018-2020 models):

- 2018: $200,000-$260,000

- 2019: $220,000-$270,000

- 2020: $240,000-$290,000

Variaxis 630 Pricing (2018-2020 models):

- 2018: $300,000-$400,000

- 2019: $350,000-$450,000

- 2020: $380,000-$480,000

The Variaxis 630 usually costs between $150,000 and $200,000 more than similar 500 models. This is because it has much better features and uses newer technology.

Total Investment Analysis

Variaxis 500 Complete Investment:

- Machine Purchase: $200,000-$280,000

- Installation/Rigging: $15,000-$25,000

- Initial Tooling: $50,000-$100,000

- Training: $25,000-$40,000

- CAM Software: $15,000-$30,000

- Total Investment: $305,000-$475,000

Variaxis 630 Complete Investment:

- Machine Purchase: $350,000-$450,000

- Installation/Rigging: $25,000-$40,000

- Initial Tooling: $100,000-$200,000

- Training: $40,000-$65,000

- CAM Software: $25,000-$50,000

- Total Investment: $540,000-$805,000

Operating Cost Analysis

Annual Operating Costs:

- Variaxis 500: $45,000-$65,000 annually

- Variaxis 630: $65,000-$95,000 annually

The 630’s higher costs are due to the need for more skilled operators, more complicated maintenance, more expensive tools, and more power use.

ROI Analysis by Application

- Job Shop Environment: The Variaxis 500 usually pays for itself in 2 to 3 years by cutting down on setup time and adding more features. The 630’s higher investment usually means that payback takes 4 to 5 years, unless a lot of work on parts is needed.

- Production Environment: The 630’s extra cost is often worth it because it cuts down on cycle time and improves quality when there is a lot of production. With the right mix of parts, you can get a return on investment in 2 to 3 years.

- Aerospace Applications: Because of the high value of parts and strict quality standards in aerospace work, both machines can get a quick return on investment. The 630’s extra features often make it worth paying more for complicated structural parts.

Application-Specific Analysis

Different manufacturing environments and part requirements make one machine much better than the other. This is why application analysis is so important for choosing the right one.

Aerospace Manufacturing

- Complex Structural Components: The 630’s bigger envelope and stronger rigidity are often needed for big aerospace brackets, wing fittings, and engine parts. If any part is longer than 18 inches, you usually need the bigger machine. If the parts are smaller, the 500 may be more cost-effective.

- Precision Requirements: Both machines meet aerospace tolerance standards, but the 630’s better rotary positioning (0.0001° vs. 0.001°) gives critical angular features more room to work. This level of accuracy is very important for parts that have tight tolerances for shape and position.

- Material Considerations: The 630’s extra spindle power and stiffness help titanium and inconel aerospace parts. The 500 cuts these materials well, but it may need to use more conservative cutting parameters, which lengthen cycle times.

Medical Device Manufacturing

- Implant Production: Hip and knee implants usually fit inside the 500’s envelope and benefit from its ability to make smooth surfaces. The medical field often prefers the smaller machine because it focuses on accuracy over size.

- Surgical Instruments: 5-axis capabilities work well on either machine for complex surgical instruments with complicated shapes. The 500’s lower investment often leads to a better return on investment for making a lot of instruments.

- Regulatory Considerations: Both machines meet the documentation and validation needs that are necessary for making medical devices. The simpler 500 may be better for validating and training operators.

Mold and Die Applications

Large Mold Sections: The 630’s extended envelope and table capacity are often needed for molds for cars and appliances. The bigger machine is needed for parts that are more than 20″ in diameter or 600 lbs.

Complex Cooling Channels: Both machines are great at making conformal cooling channels that regular machines can’t. The 630 can hold more tools, which lets it use more complicated cooling methods in bigger molds.

Surface Finish Requirements: The requirements for mold surface finish work well with both machines. The 500 often gets the same results with less money spent on smaller molds.

The Honest Verdict: Choosing Your 5-Axis Future

After inspecting hundreds of 5-axis installations over the past 37 years, here’s our honest opinion on when each machine is best for your shop.

Choose the Variaxis 500 If:

- You’re Entering 5-Axis Manufacturing: The 500 is a great way to learn about 5-axis capabilities without being too hard or expensive. With the smaller machine, most shops can handle the changes in how things work and the new skills they need to learn more easily.

- Part Size Fits the Envelope: The 500 is a great deal if your usual parts fit comfortably in 18″ x 12″ x 12″. Putting bigger parts on smaller machines causes more problems than it saves.

- Budget Constraints Matter: For smaller businesses, the $200,000+ savings in total investment is often what makes the project possible. It’s better to have a 500 than to want a 630.

- Job Shop Environment: The 500 is more versatile and can be set up faster because it can handle mixed work and different part sizes. The ease of programming is helpful when work changes often.

- Skilled Labor is Limited: The 500’s complexity is easier to handle, which is good for shops that don’t have a lot of 5-axis experience. It’s often better to learn how to use simpler tools than to try to learn how to use more advanced ones.

Choose the Variaxis 630 If:

- Large Parts Drive Your Business: If the parts are bigger than the 500’s envelope or weight capacity, the choice is made automatically. No matter how much it costs, you can’t machine something that won’t fit.

- Production Volume Justifies Investment: When you make a lot of complicated parts, the 630’s extra investment often pays off in shorter cycle times and better quality.

- Advanced Capabilities Are Essential: The 630’s features are no longer optional when part complexity needs 60-tool operations or the highest level of accuracy.

- You Have 5-Axis Expertise: Shops that already have 5-axis capabilities can make good use of the 630’s advanced features. With the right experience and help, the complexity becomes easier to handle.

- Aerospace/Medical Focus: Industries that need the best performance and accuracy often justify the 630’s higher price by the value and quality of its parts.

The Strategic Reality

It would be better for most shops to start with a Variaxis 500 and upgrade later than to start with a 630 and have too much to handle right away. Adding extra complexity to the 5-axis learning curve is not necessary.

But stores that need a lot of parts or make a lot of things may find that the 500 becomes a bottleneck very quickly. Buying the wrong machine twice costs more than buying the right machine once.

Long-Term Value and Market Considerations

Technology Evolution

The technology for 5-axis is still moving forward quickly. Both machines let you upgrade their control systems and software, but the 630’s newer platform usually supports more advanced features for longer.

Resale Value Projections

- Variaxis 500: Typically retains 45-55% of purchase price after 5 years

- Variaxis 630: Usually holds 50-60% of purchase price after 5 years

The 630’s higher retention shows that there is still a demand for large 5-axis capability and newer technology integration.

Support and Service Considerations

Both machines need special service skills. Mazaks technical support is great for both models, but the 630 may need more frequent and costly service calls because it is more complicated. – https://www.mazak.com/us-en/contact/

Conclusion: Making the Right 5-Axis Investment

Choosing between the Variaxis 500 and 630 is more than just choosing a machine; it’s a smart choice for the future of your business. Both machines can completely change your skills and place in the market if you choose and use them correctly.

The Variaxis 500 is a great way to get started with five-axis machining. It’s easy to use and doesn’t cost a lot of money. It does a good job of handling most of the hard parts while helping people learn the skills they need to grow in the future.

If shops know how to use the Variaxis 630’s advanced features, it gives them the most power. When the number of parts needed or the amount of output makes the investment worth it, it gives speed that smaller machines can’t match.

The choice you make should meet your current needs and also help you grow and learn new skills in the future. It’s better to have a Variaxis 500 that makes money than a Variaxis 630 that just sits there and waits for work to come in.

In the last 40 years, we at Premier Equipment have seen both good and bad 5-axis designs. It’s not as important to find the best specs as it is to make sure the machine can do what it’s supposed to do.

Whether you choose the 500 or the 630, you should focus on developing the programming, operating, and support skills you need to be successful with 5-axis. People who run the machine are what make it work.

This analysis represents Premier Equipment’s independent assessment based on 37 years of advanced manufacturing equipment experience. We maintain no exclusive relationships with any manufacturer, ensuring our recommendations focus solely on customer success and long-term value.