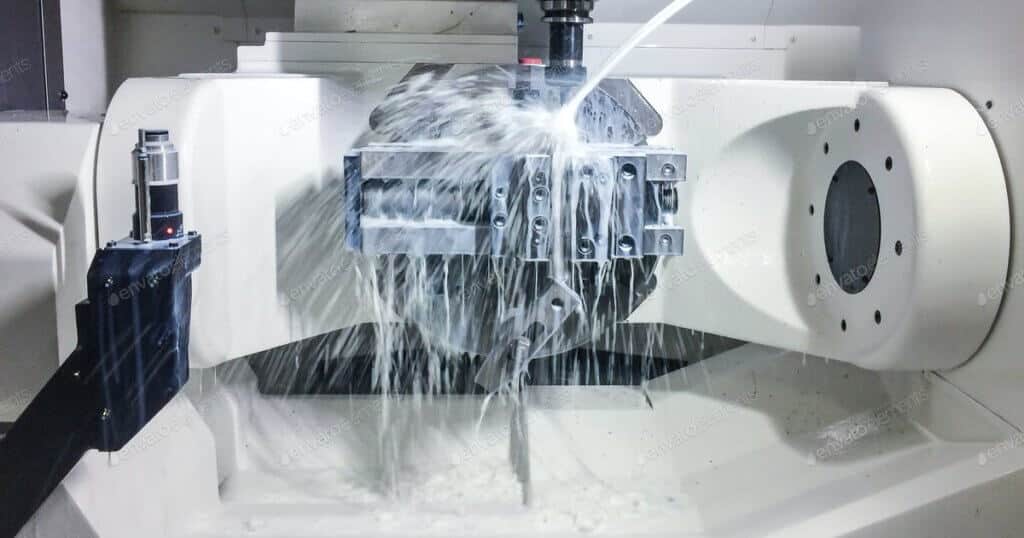

Computer Numerical Control (CNC) machines are used to manufacture many products. These machines consist of a special cutting tool and a computer that programs and controls the cutting instrument. They can make very precise and detailed cuts because they are run by a computer.

They are generally quite large, complex, and expensive machines. For this reason, a used CNC is often a more affordable option, but you need to carefully select a used machine that will work for your intended purposes. Pay special attention to what and how many cutting axes each CNC machine can work on.

What are axes in CNC machinery?

To be able to accurately determine and understand the axis type of a CNC machine, you must first understand what an axis is. An axis is a line along which a CNC machine cuts. There are three core axes; the x-axis, the y-axis, and the z-axis.

The x-axis is the vertical axis that determines the up and down movements of the cutting tool. The y-axis controls the horizontal or side-to-side movements and the z-axis determines the depth or the back and forth cuts. Beyond the core axes, there are four more axes. These other axes are created when the material, the table, or the cutting tool rotates around one of the core axes.

The higher the number of axes, the more complex the operation a CNC can handle. There are 3-axis, 4-axis, 5-axis, and 7-axis machines. Each additional axis means more intricacy and specialization. When looking for a used CNC machine for sale, you should first determine what axis it is and if that will be sufficient for your needs.

3-axis Machines

3-axis CNC machines are the simplest ones and correspondingly create the simplest parts. If you need a CNC machine to create a simple, commonplace part or to cut a small piece off of a larger piece of material, then go with a 3-axis machine. This number of axes is also great for creating holes in your material.

4-axis Machines

If you are looking to drill precise holes in the side of a material or you want to be able to cut continuously, then you want to look for a 4-axis machine. In a 4-axis machine, the machine rotates the piece around an additional axis called the A-axis so that the cuts can be made on the B-axis. Generally, these machines are a bit more expensive than 3-axis ones so searching amongst used CNC machines is probably a smart choice.

5-axis Machines

Medical equipment and auto parts industries utilize 5-axis CNC machinery. They often need more elaborate details on their parts for them to function safely and efficiently. 5-axis machines rotate two of the three components, the piece itself, the cutting spindle, or the table the piece is on, and thus form two more axes to work on.

7-axis Machines

These machines are able to handle the most complex work of all. They maneuver along all of the axes possible and often are referred to as CNC machining centers rather than simple machines. This type is primarily used for aerospace and military applications.

Now that you know what each axis number means for CNC machinery, you can better decide which type will work best for you and your needs. Find your CNC machine today and start cutting away.

Contact us to learn more about CNC Machines or find out how to purchase your own used CNC Machine.