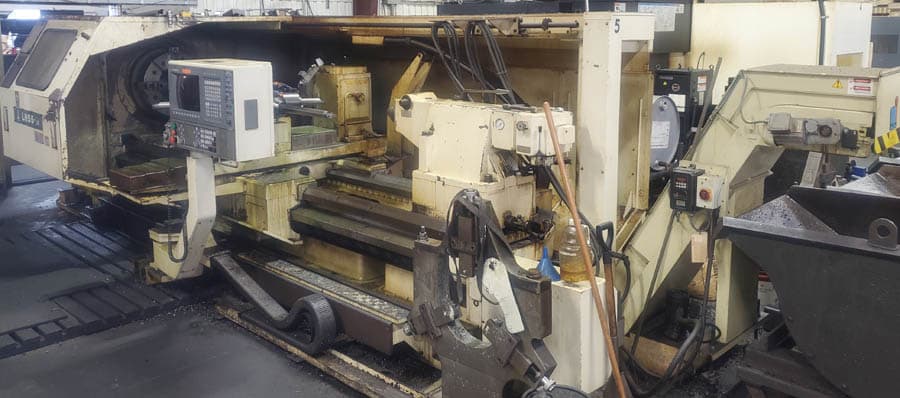

Used Okuma Lathe For Sale

Reasons to Choose an Okuma CNC Lathe Machine

The worldwide manufacturing sector selects Okuma CNC turning centers because of their exceptional precision and robust design. Okuma machines include state-of-the-art technologies together with rugged construction standards to achieve their high productivity and reliable performance.

What Makes Okuma CNC Lathes Stand Out?

The open-architecture CNC control system of Okuma CNC lathe machine tools operates under the name OSP. The system provides intuitive interface possibilities and automated features that enhance the possibilities for optimized machining procedures. Okuma machines are developed with durable components using rigorous production standards.|

Feature |

Description |

|---|---|

|

Open-Architecture Control |

OSP system for user-friendly interface and enhanced automation |

|

Customization |

Allows for superior customization in machining operations |

|

Efficiency |

Designed for enhanced efficiency in operations |

|

Durability |

Built with high-quality materials and stringent manufacturing |

How to Select the Right Okuma CNC Lathe for Your Needs

The selection of an Okuma CNC lathe requires consideration of project complexity alongside material types and production output levels. Your search for the perfect machine requires evaluation of spindle speed alongside turret configuration and optional features such as parts catchers and bar feeders.

| Series | Description | Popular Models |

|---|---|---|

| GENOS Series | High-performance, affordable, and easy-to-use lathes with Okuma's Thermo-Friendly Concept for high precision. | GENOS L3000-e, GENOS L2000-e |

| LB2000 Series | Compact and highly versatile 2-axis lathes, ideal for high precision and rigidity in small parts production. | LB2000 EX III |

| LB2500 Series | Mid-sized lathes designed for multitasking and heavy-duty machining with high torque and productivity. | LB2500 EX II |

| LB3000 Series | High-performance lathes offering speed, rigidity, and precision, suitable for a range of applications. | LB3000 EX II, LB3000 EX III |

| LB4000 Series | Large, heavy-duty lathes for complex and large part machining with excellent accuracy and rigidity. | LB4000 EX II, LB4000 EX III |

| MULTUS Series | Multi-tasking lathes combining turning, milling, and drilling in one setup, ideal for complex part production. | MULTUS U3000 |

| LB35 Series | Heavy-duty lathes designed for larger part production with high cutting capacity and precision. | LB35II |

| LT2000 EX Series | Twin-spindle lathes offering simultaneous machining for increased throughput and flexibility. | LT2000 EX |

| LT3000 EX Series | High-rigidity twin-spindle lathes for complex part machining with options for dual turret configurations. | LT3000 EX |

| LU3000 EX Series | Multi-function lathes designed for large part production with dual turrets for simultaneous operations. | LU3000 EX |

Additional Okuma Lathe Features

Additional features installed on your Okuma lathe will boost both its operational efficiency and functionality. Chips can successfully be transported by a chip conveyor device to create safer workshop areas and the tailstock delivers additional rigidity support for longer materials. A spindle cooling system integrated into your machine enables stable operation when running extended periods. The combination of twin turret and sub spindle features on machines allows users to perform complex multi-tasking operations. Select big bore capabilities when your work involves processing larger diameters. The machine can achieve smoother finishes through the addition of grinder attachments. The Cadet and other vertical and horizontal machining centers from Okuma deliver precise and fast operations which create a flexible and robust system.Used Okuma Turning Centers

The Okuma turning centers operate as flexible machines which deliver precise turning operations. The centers provide multiple turrets and live tooling features which enable them to produce complex parts effectively. The Okuma Multus series models provide users with additional sophisticated features that enable simultaneous 5-axis machining.

The Advantages of Okuma's Multus Series

The Okuma Multus series displays the highest position among multifunctional machining centers. The machines unite three operations into one machine setup enabling rapid production cycles and improved output levels. The machines have durable designs and intelligent controls that allow their deployment across numerous industrial needs.

Customer Support and Services from Okuma Machinery

Okuma delivers outstanding customer support and maintenance services to help their machines run efficiently from installation until their end of service.

Okuma provides extensive training and technical assistance together with access to a skilled workforce network. The company offers after-sales service packages which help customers boost productivity while minimizing operational expenses.

Okuma CNC Lathe Takeaways

- Robust and Precise: Okuma lathes demonstrate exceptional durability together with high precision levels.

- Advanced Controls: The OSP control system enables users to produce customized work along with increased operational efficiency through its advanced controls mechanism.

- Diverse Product Line: Okuma provides customers with a broad selection of lathes which address different machining requirements.

- Cost-Effective Options: Certified used Okuma lathes offer great value.

- Turning Centers: Okuma turning centers deliver versatility to handle complex parts effectively.

- Multifunctionality: The Okuma Multus series enables users to perform extensive operations through a single machine setup.

- Customer Services: Okuma provides their customers with broad service networks and extensive support for their machines.