What Makes Smart Machine Tool Stand Out?

Delivering value without sacrificing quality is how Smart Machine Tool established its reputation. With the support of a parent company that has been a distributor for more than 35 years and an importer for more than 20 years, the company's founders have combined more than 100 years of experience developing CNC lathes. Machines that comprehend actual shop floor needs are a direct result of this extensive industry knowledge.

Because the company uses Fanuc controls for all of its products, operator training is simple and downtime during transitions is minimized. With Smart's emphasis on rigidity, accuracy, and user-friendliness, you can spend more time creating parts and less time battling with your equipment, whether you're managing a production facility or a job shop.

Smart Machine Tool Product Lines

CNC Lathes

A wide variety of 2-axis and 3-axis CNC lathes with box way construction for optimal rigidity are available from Smart. With choices for live tooling, sub-spindles, and programmable tailstocks, the NL series includes everything from small 6" chuck models (NL1500) to powerful 24" chuck machines (NL6000 series).

Popular Models: NL2000M, NL2500M, NL3000BM, NL4000M, NL5000M

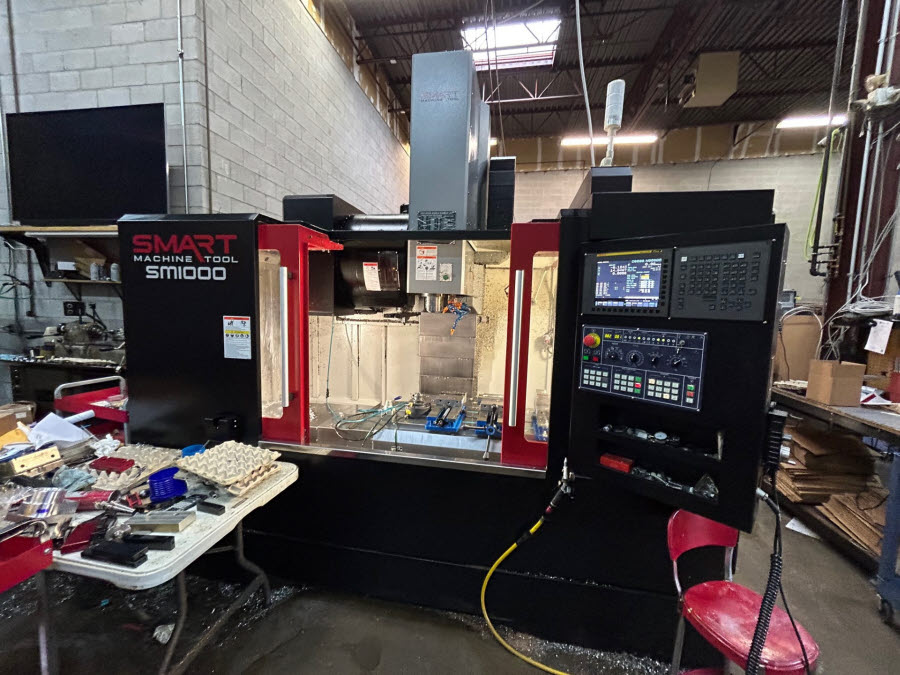

Vertical Machining Centers

With CAT40 tooling and 12,000 RPM spindles, the SV series offers precision work. The SM series offers up to 50 HP spindles and box way construction with CAT50 tooling for heavier applications.

Popular Models: SV1, SV2, SV3, SM1100-50, SM1682-50

Horizontal Machining Centers

With a 50 HP direct drive spindle and industry-leading tapping cycles, the SX4000 twin-pallet system offers high production capability and is ideal for lights-out manufacturing.

Bridge Mills & Specialty Equipment

Bridge mills from Smart's HSA and SW series use CAT50 tooling to handle large workpieces. For specific uses, the HNK line consists of horizontal boring mills and vertical turning lathes.

Enhance Functionality with Extra Options

Smart machines can be customized with:

- Robotic loaders and bar feeders for automation

- Chip conveyors and coolant management systems

- Tool presetters and probing systems

- Live tooling packages for turning centers

- Sub-spindle configurations for complete part machining

Frequently Asked Questions

What control system do Smart Machine Tool machines use?

Throughout their whole product line, Smart Machine Tool only uses Fanuc controls. This standardization guarantees long-term parts availability and makes programming consistent whether you're running a mill or a lathe.

Are Smart Machine Tool machines suitable for production environments?

Of course. Heavy-duty parts made for continuous operation and box-way construction provide rigidity in smart machine tool machines. Numerous shops use highly reliable Smart equipment in high-volume production.

How does Smart Machine Tool pricing compare to other brands?

With prices that are usually 20–30% lower than those of similar Japanese equipment while still upholding quality standards, Smart Machine Tool markets itself as a value brand. Used Smart machines are even more affordable, which makes them perfect for stores looking to replace outdated machinery or increase capacity.

Why Buy a Used Smart Machine Tool from Premier Equipment?

When you buy a used Smart machine tool from Premier Equipment, you receive quality equipment for 40–60% less than new. Before any machine is delivered to your shop floor, our skilled technicians perform a comprehensive inspection to make sure it satisfies our quality standards. Our staff can help you choose the best model to meet your production requirements and budget thanks to our daily updated inventory and technical knowledge of smart machines.

Resources

Customer Care and Technical Support

- Smart Machine Tool Website: https://www.smartmachinetool.com/

- Phone: (855) 637-3220

- Sales Contact: Nicholas Layo

- Service Contact: Dane Kilpatrick

- Headquarters: N25 W23287 Paul Rd Pewaukee, WI 53072

Online Resources

- Official Website: https://www.smartmachinetool.com/

- LinkedIn: https://www.linkedin.com/company/smartmachinetool

Vertical Machining Centers

| Model | X Travel (in) | Y Travel (in) | Z Travel (in) | Optional Enhancements (typical) |

|---|---|---|---|---|

| SMART MINI – Linear Way (CAT40, 12K) | 23.6 | 17.7 | 19.7 | Compact footprint, 4th-axis rotary, probing, chip conveyor, coolant-thru spindle |

| SV 1 – Linear Way (CAT40, 12K) | 23.6 | 17.7 | 19.7 | 24-tool ATC, 4th-axis rotary, work probing, spindle chiller, CTS |

| SV 2 – Linear Way (CAT40, 12K) | 31.5 | 19.7 | 19.7 | 30-tool ATC, 4th-axis rotary, probing, chip conveyor, CTS |

| SV 3 – Linear Way (CAT40, 12K) | 41.34 | 20.47 | 20.47 | 30-tool ATC, 4th-axis rotary, CTS, spindle probe/tool setter |

| SV 4 – Linear Way (CAT40, 12K) | 51.18 | 25.59 | 23.62 | Big table, 30-tool ATC, 4th-axis rotary, CTS, chip conveyor |

| SV 5 – Linear Way (CAT40, 12K) | 51.18 | 27.56 | 27.56 | High Z clearance, 30-tool ATC, rotary tables, CTS, probing |

| SV 6 – Linear Way (CAT40, 12K) | 63 | 31.5 | 31.5 | Large envelope, 30-tool ATC, 4th/5th-axis options, CTS, chip conveyor |

| NV 5500L – Linear Way (CAT40, 12K) | 53.15 | 22.44 | 20.8 | High-speed machining, 30-tool ATC, rotary tables, CTS, probing |

| SM 1100-50 – Box Way (CAT50, 6K) | 43.31 | 23.62 | 24.8 | Heavy-duty 50-taper, 32-tool ATC, high-torque spindle, CTS, chip conveyor |

| SM 1370-50 – Box Way (CAT50, 6K) | 51.18 | 27.56 | 25.98 | 35/30 hp spindle, 30-tool ATC, rotary axes, CTS, through-tool air |

| SM 1682-50 – Box Way (CAT50, 6K) | 62.99 | 32.28 | 25.98 | Large table, 40-tool ATC, 50-taper torque package, CTS, probing |

| SM 1682-50 – Box Way (CAT50, 12K) | 62.99 | 32.28 | 25.98 | High-speed 12K spindle, 40-tool ATC, CTS, rotary tables, chip conveyor |

| SM 2082-50 – Box Way (CAT50, 6K) | 81.1 | 32.28 | 32 | Long X travel, 40-tool ATC, heavy-duty spindle, CTS, probing, chip management |

| SM 2110-50 – Box Way (CAT50, 6K) | 82.68 | 40.16 | 32.28 | Wide Y travel, 40-tool ATC, 50-taper torque, CTS, rotary & 5-axis options |

Horizontal Machining Centers

| Model | X Travel (in) | Y Travel (in) | Z Travel (in) | Optional Enhancements (typical) |

|---|---|---|---|---|

| SX 4000 | 22.05 | 22.05 | 27.17 | Full 4th-axis rotary table, pallet changer, 60-tool ATC, CTS, probing |

Drill Tap / Mill Machines

| Model | X Travel (in) | Y Travel (in) | Z Travel (in) | Optional Enhancements (typical) |

|---|---|---|---|---|

| KM 450D – Linear Way (CAT40, 12K) | 27.6 | 17.7 | 18.9 | High-speed drilling/tapping, 30-tool ATC, conveyor, CTS, probing |

| KT 360D – Linear Way (BT30, 15K) | 20.5 | 14.2 | 11.8 | BT30 15K spindle, 14-tool ATC, automation loading, probing |

| KT 420AL – Linear Way (BT30, 15K) | 27.5 | 16.5 | 11.8 | Auto loader-friendly, 20-tool ATC, probing, chip conveyor |

| KM 450DH – Linear Way (CAT40, 12K) | 22 | 16 | 16.9 | Dual-purpose mill/tap, 2–26 tool capacity, rotary options, probing |

Bridge Mills

| Model | X Travel (in) | Y Travel (in) | Z Travel (in) | Optional Enhancements (typical) |

|---|---|---|---|---|

| HSA 2212 – Bridge Type (CAT50, 12K) | 88.58 | 47.24 | 30.71 | 40-tool ATC, angle heads, extended tables, CTS, rotary axes |

| HSA 3212 – Bridge Type (CAT50, 6K) | 127.95 | 47.24 | 30.71 | Long X travel, 40-tool ATC, CTS, floor-plate fixturing options |

| HSA 323 – Bridge Type (CAT50, 6K/12K) | 118.11 | 90.55 | 30.71 | Wide Y, 6K or 12K spindle, 40-tool ATC, CTS, 4th/5th-axis heads |

| HSA 423 – Bridge Type (CAT50, 6K/12K) | 157.48 | 90.55 | 30.71 | Large bridge envelope, 40-tool ATC, CTS, heavy-duty fixturing |

| HSA 523 – Bridge Type (CAT50, 6K/12K) | 196.85 | 90.55 | 30.71 | Ultra-long X travel, 40-tool ATC, CTS, rotary tables, angle heads |

| SW 216 – Bridge Type (CAT50, 6K) | 82.68 | 62.99 | 30.71 | 40-tool ATC, CTS, heavy-duty bridge, multiple head options |

| SW 316 – Bridge Type (CAT50, 6K) | 122.05 | 62.99 | 30.71 | Large-part machining, 40-tool ATC, CTS, probing |

| SW 323 – Bridge Type (CAT50, 6K) | 118.11 | 90.55 | 30.71 | Wide-span Y, 40-tool ATC, CTS, rotary axes |

| SW 423 – Bridge Type (CAT50, 6K) | 157.48 | 90.55 | 30.71 | Long-bed bridge, 40-tool ATC, CTS, floor-plate options |

| SW 523 – Bridge Type (CAT50, 6K) | 196.85 | 90.55 | 30.71 | Very long X, 40-tool ATC, CTS, extended fixturing |

| SW 623 – Bridge Type (CAT50, 6K) | 236.22 | 90.55 | 30.71 | Maximum X travel, 40-tool ATC, CTS, large-part & mold work |

Horizontal Boring Mills – HNK

| Model | X Travel (in) | Y Travel (in) | Z Travel (in) | Optional Enhancements (typical) |

|---|---|---|---|---|

| HB-110M | 62.9 | 59 | 39.3 | W-axis 13.7", rotary table, extended tooling, probing, ATC options |

| HB-130S | 59.1 (78.7 opt.) | 59 | 51.2 | Extended X travel option, large rotary table, ATC, facing head, probing |

| HB-130 | 118.1 | 90 | 51.2 | Heavy rotary table, ATC, floor plates, extended W-axis, probing |

| HB-130X | 157 | 98 | 63 | Extra-long X, high table load, ATC, extended W-axis, probing |

| HB-130C | 118.1 | 78.7 | 51.2 | Compact Y with large table, ATC, rotary options, probing |

| HB-130CX | 157.5 | 90.6 | 51.1 | Long X, extended table, ATC, W-axis options, probing |

| HB-150 | 118.1 | 90.6 | 63 | High-capacity table, ATC, facing heads, probing |

| HB-150X | 157 | 98 | 78 | Extra-long X and Z, heavy-duty boring, ATC, W-axis, probing |

| HB-150LH | 157 | 98 | 63 | Long X, elevated column (LH), ATC, W-axis, large rotary table |

| HB-150LHX | 196.8 (236.2 opt.) | 137.8 | 78.7 | Max envelope, extended X/W, very large rotary table, ATC, probing |