Used 5 Axis CNC machine for Sale at Premier Equipment

Explore Our Selection of 5 Axis CNC Machines

As a leading used heavy machinery dealer, we have a large inventory of used CNC 5 axis machining centers.

From 5 axis mill, vertical to horizontal, with options like tool changers, chip conveyors, pallet changers, and sub-spindles.

Let our team of experts help you find the right machine for your project.

What is a 5-Axis CNC Machine?

A 5-axis CNC machine allows a cutting tool along five axes simultaneously, instead of three (X ,Y , and Z), as with conventional 3-axis CNC machines.

The 5-axis machining center provides greater accuracy for machining complex parts and greatly reduces manual load handling and setup times. This is relevant within markets such as aerospace, automotive, and medical manufacturing.

Many 5 axis machines include higher RPM, with workpiece options and Z-axis for dual spindle applications.

5 Axis machines are also available as CNC routers.

5 Axis CNC Mill

The 5-axis CNC mill functions as a machine tool which enables material cutting and shaping from various directions. A 5-axis mill extends the basic three-axis movement system of standard CNC mills by adding two axes through which there is rotation on both the X axis (A axis) and the Y axis (B axis).

The machine tool can access the workpiece from almost any direction, which enables

- The machine produces multiple-angled 3D parts in just one setup process

- Machine hard-to-reach areas

- Cut undercuts and intricate contours

- The machine eliminates the requirement for multiple setups and fixtures.

5 Axis CNC mill Brands and Models

| Brand | Entry-Level Models | Mid-Range Models | High-End Models |

|---|---|---|---|

| DMG MORI | DMU 50 | DMU 95 monoBLOCK | DMC 65 monoBLOCK |

| Haas | UMC-500 | UMC-750 | UMC-1000 |

| Hurco | VMX30Ui | VMX42SRTi | VC500i |

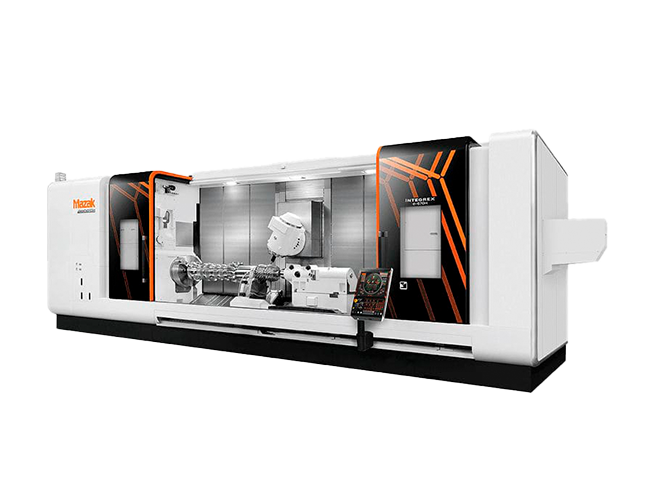

| Mazak | VARIAXIS i-300 AWC | VARIAXIS i-600 | INTEGREX i-Series |

| Okuma | MU-5000V | MU-6300V | GENOS M460V-5AX |

A 5 axis CNC mill comes in basic entry-level models to advanced industrial units. Less complex 5 axis mills start at $150,000 while more industrial 5 axis CNC mills can cost more than $1 million when buying new. When you buy used from Premier Equipment, you save about 40% - 50% of a new machine, at the end costing you between $60,000 and $500,000 for these machines.

5 Axis CNC Lathe

The five-axis CNC lathe functions as a mill-turn center or multi-tasking machine which executes both lathe turning and sophisticated milling processes. In addition to standard lathe operations, which involve workspace rotation and tool-based part cutting for cylindrical shapes, a 5-axis lathe includes:

- The main spindle rotation (C-axis)

- The traditional X and Z linear movements

- A B-axis milling head functions by rotating its axis.

- The Y-axis functions for performing off-center milling operations

Through its combined funcfunctionality,lity the 5-axis CNC lathe operates as a traditional lathe for turning cylinders, yet molds complex geometries from various directions. The integrated 5 axis CNC lathe finishes multiple parts during one setup, which separates it from conventional machinery and enables it to work on intricate shapes that extend beyond the middle section of a component. A 5 Axis CNC lathe allows you to machine gear teeth and hexagonal shapes apart from cylindrical components, offering versatility in more complex manufacturing projects.

5 Axis CNC lathe Brands and Models

| Brand | Entry-Level Models | Mid-Range Models | High-End Models |

|---|---|---|---|

| DMG MORI | CTX beta 800 TC | NTX 2000 | NTX 3000 |

| Mazak | INTEGREX i-200 | INTEGREX i-400 | INTEGREX e-800H |

| Okuma | MULTUS U3000 | MULTUS U4000 | MULTUS U5000 |

| Doosan | PUMA SMX2600S | PUMA SMX3100S | PUMA SMX5100L |

| Nakamura-Tome | JX-250 | NTRX-300 | WY-300 |

The price of a 5 axis CNC lathe (mill-turn center) has broad variations that depend on its functional capacity and machine size. The cost for new basic 5-axis lathes starts at around $200,000; brands with more industrial 5 axis models equipped with full mill-turn functions can go above $1.5 million during the initial purchase. The starting price point exceeds that of 5 axis mills because these machines combine complex construction with double functionality.

Premier Equipment offers customers a price discount that reaches 40-60% off new prices starting at $70,000, while top-end systems cost about $750,000+. The price range of these machines stems from various characteristics, including production year, along with machine operational hours, work envelope dimensions, turret amounts, sub-spindle capabilities, tool capacity, and manufacturing processing refinement.

Why Buy Used CNC 5 Axis CNC Machines from Premier Equipment?

Here are four reasons why buying a used 5-axis CNC from Premier Equipment is worth it.

- Affordable CNC Machines: You can save thousands of dollars by buying used machinery as opposed to new. Our selection of used turning and milling inventory is inspected for quality, helping machine shop owners save money without having to sacrifice quality.

- Quality Inventory: When it comes to our CNC machining center inventory, we make sure each machine goes through a rigorous inspection and maintenance process so they are production line ready. Our quality used inventory includes brands like DMG Mori, Mazak, Mori Seiki.

- One Stop Shop: Because we carry nearly every type of used CNC Heavy Equipment that is available, Premier can ensure you have the machines and features you need to stay productive with your CNC 5-axis machining center.

- Dedicated Support: Our CNC experts are here to help you choose the right machine and answer any technical questions.

At Premier Equipment we have the right used 5 axis CNC milling machine or lathe, vertical, or horizontal ready to make parts. Give our team a call and we will help you find what you need.