CNC machines provide pinpoint-accurate milling services for a variety of materials, which is why they’re indispensable for fabrication companies. Home crafters, makers, and artisans don’t have to miss out on the benefits of CNC fabrication, though. While it’s true that full-sized machines are often quite expensive when they are showroom new, used equipment is substantially more affordable for small shops and individual creators. Mini CNC rigs are also considerably less expensive than their larger siblings if that is more your size.

When you’re proactive about searching for opportunities to buy used CNC machines, you can often find deals that put them in your shop for around the same price you’d pay for other maker tools like your home 3D printer. If you’re still wondering if you should make the leap, here are five reasons why your shop would benefit from having an in-house CNC machine.

-

Customization and Personalization on Every Project

A good CNC machine gives you the chance to fully personalize every piece you do. From individualized engravings to unique woodworking embellishments that tell the story of each piece you create, the possibilities for presenting truly individualized products are practically endless. Precision engraving also allows you to take your designs to the next level, confidently executing more precisely controlled patterns and images than ever before, in a fraction of the time it would take to hand-engrave the same visual elements.

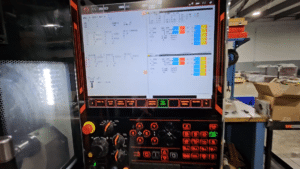

Check out our Haas VF2 and VF3 Series

-

Increased Production Capacity

More and more, hobbyist makers are finding new career opportunities in the crafts they have mastered. Whether it’s selling custom knife work after documenting the processes used to make it online, offering finished products through storefront sites, or you’re just making things you need to improve life around the house. There are a lot of reasons to want to do more with your project hours. Used CNC machines provide a relatively low-cost way to get a machine into your shop. If you use your skills to earn a little side money, the increased capacity makes it easy to pay for the machine with its own output.

-

CNC Machines Are Beginner-Friendly

The scripts used to define CNC router patterns are relatively easy to learn, in no small part because of the large base of makers using them and sharing tips online. A little search will bring you a lot of options for professionally edited books on getting started, authoritative online guides with both readings and video demonstrations. There are also online forums and communities filled with CNC enthusiasts who can help you master the ins and outs as a beginner. The commands are relatively straightforward, too, and that’s one of the reasons used machinery dealers find it so easy to place CNC equipment with buyers. They’re in high demand perennially as makers expand their shops and cycle out their old models for newer ones with more options.

-

CNC Equipment Optimizes Material Use

When you can count on computer-precise fabrication that is automatically executed to specification, you minimize the amount of scrap waste produced by the process as well. Not only does the precision offered by this process result in fewer mistakes and scrapped attempts, buying a used CNC machine for sale is a great way to use less raw material in the manufacture of your goods overall. Hand engraving and fine woodwork tends to remove a lot more material than computer-guided CNC processes do, so you have a lot less lying on the shop floor at the end of the day.

-

Consistent Results

The computer-aided nature of CNC milling makes it precise within very easily quantified tolerances, and as a result, you can easily reproduce the same results again and again as long as you repeat the same program and start with the same materials and dimensions. There are very few processes you can set up in a small shop that get results more tightly distributed than this. None that do at the level of resource efficiency that you will find with CNC equipment. The only process that is comparable for precision is 3D printing, mainly because it uses a similar computer-aided interface.

Use machinery dealers understand this, which is why they make a point of bringing used machines to market. If you haven’t invested in used CNC machines yet, why wait? Improve your project time and overall efficiency today. Contact us for a quote today! Also, check out our financing options for purchasing a used CNC machine.