The integration of additive and subtractive processes in the ever changing manufacturing landscape is a revolution in itself and Mazak, a leading CNC machine tool manufacturer, has been a pioneer in this revolution. Mazak has been recorded with innovation and excellence in metalworking technology for more than a century. In this article, we explore Mazak’s major contributions to hybrid manufacturing and the far reaching implications of these advances for the industry.

The Evolution of Hybrid Manufacturing

Hybrid manufacturing is a paradigm shift from prior methods in the sense that these two processes are combined to harness the strengths of each process. Additive manufacturing, a phrase we often associate with 3D printing, is where a part is built layer by layer; subtractive manufacturing uses cutting or drilling for removing material. For Mazak to enter this field was to benefit from the best of both worlds.

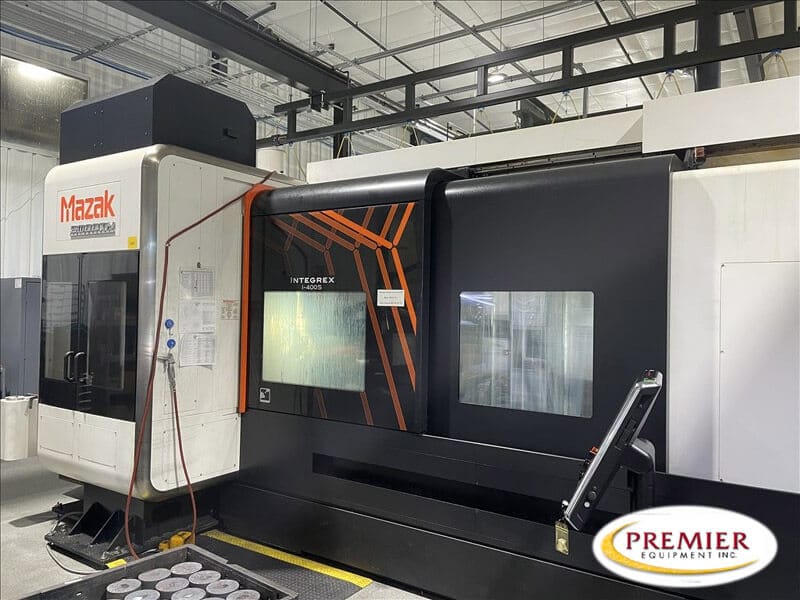

Mazak’s entry into hybrid manufacturing was the Integrex i-400AM, a machine that combines additive and subtractive capabilities in one. With this machine, metal can be deposited via laser cladding, and then machined in a single setup, reducing production time and increasing part complexity.

See our Mazak Integrex in stock >

Technological Innovations and Integration

Mazak’s hybrid machines are based on a solid foundation of advanced technologies. For example, the Integrex i-400AM has a multi tasking design with a spindle for machining and a laser head for additive processes. With this integration, manufacturers can manufacture complex parts featuring internal structures and geometries that simply would not be possible, or would be prohibitively expensive, to achieve using traditional machining alone.

Laser cladding technology is one of the key innovations in Mazak’s hybrid machines. The process of depositing metal onto a substrate using a high powered laser creates complex shapes and repairs worn or damaged components. When combined with subtractive machining, this technology enables new part design and fabrication possibilities.

Industry Implications and Adoption

Mazak’s hybrid manufacturing solutions are having an impact in aerospace, automotive and medical device manufacturing. For example, in aerospace, the ability to make complex geometries and internal structures without having to set up multiple times or perform post processing operations is a game changer. It allows lighter, stronger, components to be produced that meet industry standards at a number.

Hybrid manufacturing has been shown in the automotive sector for the rapid prototyping and manufacturing of complex parts like engine components as well as gearbox housings. Mazak’s hybrid machines provide the precision and speed to reduce lead times and improve overall product quality.

Future Outlook and Challenges

Several challenges and opportunities are on the horizon as hybrid manufacturing continues to evolve. The main problem is that we need skilled operators who can operate these sophisticated machines. To tackle this, Mazak has taken action through training programmes and forging relationships with educational establishments to create the manufacturing professionals of the future.

Technologically speaking, software and control systems must advance. Mazak has been a pioneer in developing sophisticated control systems that optimise both additive and subtractive processes, and provide seamless integration and high quality output.

Hybrid manufacturing also has the potential to drive sustainability in production, which is the future of hybrid manufacturing. Hybrid processes help to reduce material waste and energy consumption and so may have a large role to play in environmentally friendly manufacturing practice. As well, Mazak is committed to innovation and sustainability, and is a leader in this area.

Conclusion

Mazak is a pioneer in the use of hybrid manufacturing techniques, due to their dedication to innovation and aiding their vision for the future of manufacturing. Mazak has combined additive and subtractive processes to open up new part design, production efficiency and quality avenues.

With the manufacturing landscape continuing to change, it is apparent that hybrid manufacturing will become a more and more significant part of the manufacturing mix. Mazak is leading the way in driving technological advancements and industry adoption, and the future is bright for manufacturers in all sectors. In aerospace, automotive and any other field where precision and innovation are needed, Mazak’s hybrid solutions are set to change what is possible in modern manufacturing.

View our Used Mazak Inventory today!

References:

[1] Mazak Corporation – , https://premierequipment.com/wp-content/uploads/2024/11/integrex_i-am_series.pdf

[2] Mazak’s Hybrid Multi-Tasking Machines – https://premierequipment.com/cnc-blog/mazak-hybrid-multi-tasking-cnc-machines/

[3] Phillips Corp, “Hybrid Manufacturing: The Future of Production”, https://phillipscorp.com/india/hybrid-additive-manufacturing-shaping-the-future-of-production/