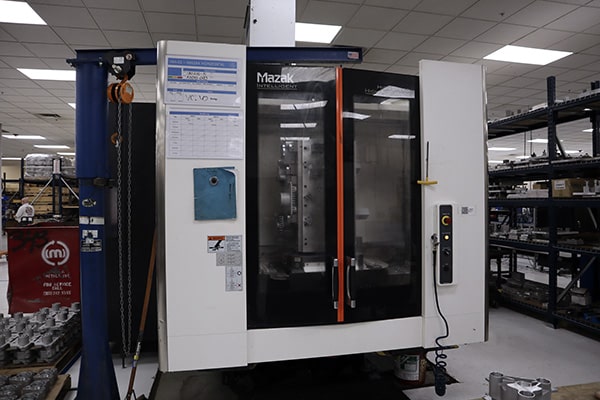

Used Horizontal CNC Mill

Used CNC horizontal mill Inventory

Premier Equipment provides manufacturers with a full range of

used horizontal CNC mill that offer economical production solutions for high-volume manufacturing needs.

Maximizing Productivity Through Horizontal CNC Mills

Horizontal CNC mills achieve high productivity levels because of their distinctive engineering features. Multi-pallet systems support uninterrupted production operations during loading and unloading procedures, thus minimizing production interruptions.

The horizontal setup enhances chip removal through natural gravity action, which prevents recutting while improving surface quality. The orientation enables operators to access multiple workpiece faces during single setup operations, which reduces overall setup time.

Enhanced Performance and Stability

Horizontal machines display exceptional rigidity which enables them to deliver precise results during intense heavy cutting operations. Tool life extends significantly because of enhanced chip evacuation and coolant delivery capabilities which the machine's inherent stability further enhances through its production of superior surface finishes. Horizontal mills demonstrate exceptional suitability for automated manufacturing systems because their features enable extended production durations with minimal operator involvement and consistent product quality.

Advanced Features and Capabilities

Modern horizontal CNC mills exhibit advanced operational features and extreme versatility due to their design. Standard equipment features pallet changers for continuous machining together with large tool magazines which support between 40 and more than 200 tools. Horizontal mills equipped with through-spindle coolant technology maintain effective cooling whileostreaming chips before and during deep-hole drilling procedures.

Standard equipment on modern horizontal mills includes 4th axis rotary tables which work in combination with optional 5th axis trunnion tables to handle complex part geometries. The combination of advanced chip management systems with conveyors and filtration units both preserves a clean workspace and enables machines to operate without human supervision for extended durations.