LNS's CNC Machining Know-How

LNS has really made a name for itself when it comes to CNC machining. They're known for coming up with smart solutions that help make production smoother and ramp up output. Their crew of skilled engineers and techs really gets what modern machining businesses struggle with. This allows them to create top-of-the-line products that tackle these problems head-on. When you opt for used LNS CNC machines from Premier Equipment, you’re tapping into this deep expertise and benefiting from years of innovation in the industry.Key Features and Capabilities of LNS CNC Solutions

LNS is known worldwide for being a top player in CNC machining. They keep coming up with smart solutions that make production smoother and boost output. Their skilled team of engineers and technicians really gets what today's machining operations deal with, allowing them to create cutting-edge products that tackle these problems directly. When you choose used LNS CNC machines from Premier Equipment, you're tapping into this knowledge and benefit from years of top-notch innovation.Key Features and Skills of LNS CNC Solutions

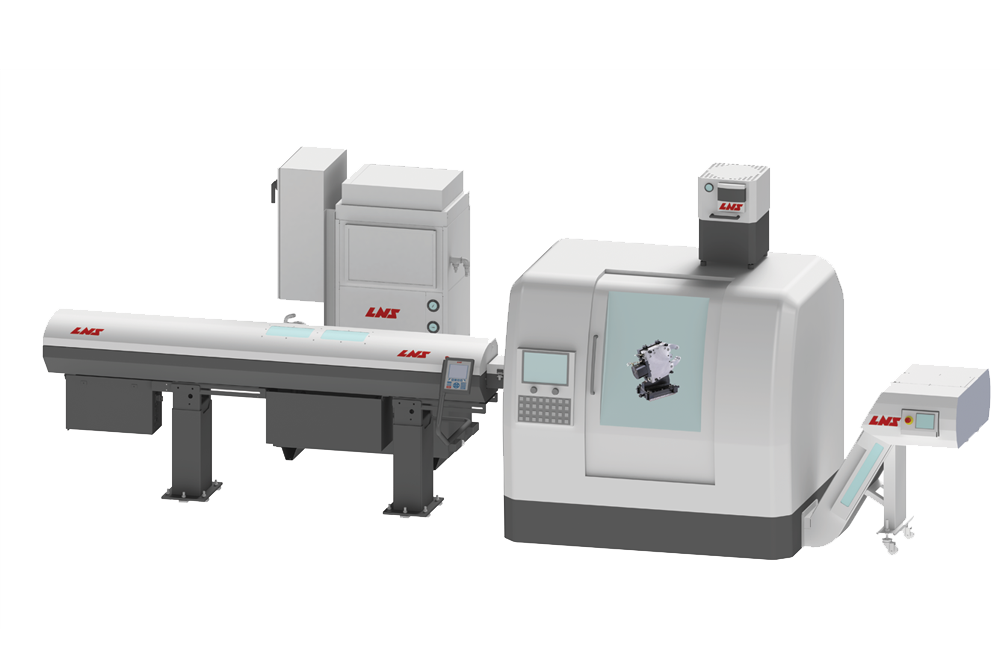

LNS CNC machines have a solid rep for being high performers and adaptable thanks to their extensive industry experience. Their advanced bar feeding tech is a key part of their design, featuring smart loading systems that ensure materials are handled accurately and consistently, which really cuts down on operational downtime. The company's clever way of managing chips has led to conveyor systems that work fast to get rid of debris and keep a tidy, safe workspace needed for continuous operation. Plus, their advanced coolant management systems are another strong point of LNS tech, helping to extend tool life and improve surface finish quality. They also focus on workspace safety with top-notch air filtration systems that keep the air clean and protect operators. On top of that, LNS developed flexible work support systems that can handle a variety of part sizes and shapes, ensuring stable and accurate workpiece holding during machining.Common Uses and Industries

The industrial applications of LNS CNC machines extend to automotive and aerospace sectors while also fulfilling requirements of medical device production and generic manufacturing needs. The machine excels in turning and milling operations at high manufacturing volumes specifically for producing complex shapes within strict tolerances. The machines have the capacity to operate on a wide material range that includes basic steel grades alongside the advanced alloys of titanium alongside aluminum and various engineering plastic materials.LNS CNC Equipment's Competitive Edge

The distinctive features which separate LNS CNC equipment when compared with other CNC manufacturers become apparent. Customers enjoy machines from LNS because they deliver reliable performance and reduced maintenance requirements and financial expenses. LNS equipment demonstrates accurate engineering because it makes high-quality parts and achieves optimized run times which minimize equipment downtime while boosting operational productivity. Existing manufacturing systems benefit from the easy integration of these machines which include user-friendly interfaces.Perks of Choosing LNS CNC Machines

Premier Equipment provides substantial opportunities to manufacturing operations through their used LNS CNC machine marketplace. The purchasing of used LNS CNC equipment through Premier Equipment delivers advanced CNC technology at budget-friendly prices as compared to fresh devices. Buyers who get machines from Premier Equipment experience increased productivity alongside better efficiency and improved quality and consistency. LNS machines' reliable operating nature reduces maintenance services along with equipment breakdown duration thus aiding businesses in market competition.Why Buy from Premier Equipment

The main focus at Premier Equipment consists of providing satisfied customers through top-quality second-hand CNC machine products. The equipment maintenance services of our company involve complete machine examinations combined with maintenance activities to ensure seamless operation. Customers who need different solutions receive competitive rates and adaptable payment arrangements from our company. The skilled team at Premier Equipment will assist you in selecting proper equipment while providing sustained post-sales technical assistance. Your production site will receive swift delivery service as part of our offerings. With our widespread knowledge of LNS CNC machines we help customers get suitable tools that match their specific machining requirements for achieving LNS performance standards.Technical Specs Experts

Our inventory features a wide variety of used LNS CNC machines which fulfill numerous machine requirements. Potential customers need to speak with our friendly sales team for complete information about particular machine specifications. The sales team at Premier Equipment will happily guide you toward an LNS CNC machine ideal for manufacturing your products. Acquire used LNS CNC machines right now from Premier Equipment to experience the exceptional operational efficiency together with the astounding precision and trustworthiness that defines LNS as a global leader in CNC machining.| Model | Bar Diameter Range | Max Bar Length | Type | Notes / Features |

|---|---|---|---|---|

| LNS Express 220 S2 | 3 – 23 mm | 2,000 mm (approx. 6.5 ft) | Short Bar Feeder | Compact design; ideal for small-diameter bars |

| LNS Alpha 552 | 5 – 51 mm | 3,700 mm (approx. 12 ft) | Hydrodynamic Bar Feeder | High-speed operation; stable bar support for Swiss-style lathes |

| LNS Alpha ST 320 | 3 – 20 mm | 3,200 mm (approx. 10.5 ft) | Hydrodynamic Bar Feeder | For small-diameter bars; suitable for Swiss turning centers |

| LNS Quick Load Servo 80 S2 | 3 – 80 mm | 1,500 mm (approx. 5 ft) | Short Bar Loader | Servo-controlled for quick setups; user-friendly interface |

| LNS Sprint 3 | 3 – 23 mm | 3,200 mm (approx. 10.5 ft) | Hydrodynamic Bar Feeder | Compact, robust design; offers quick changeovers |

| LNS Sprint 538 | 5 – 38 mm | 3,800 mm (approx. 12.5 ft) | Hydrodynamic Bar Feeder | Quick diameter adjustments; stable bar feeding at high RPM |

| LNS Hydrobar HS | 2 – 26 mm (varies by model) | Up to 3,200 mm | Hydrodynamic Bar Feeder | Classic LNS design; known for reliability and performance |

| LNS Quick Six | 6 – 65 mm | 3,200 mm (approx. 10.5 ft) | Short Bar Loader | Reduces remnant length; servo-driven pusher |