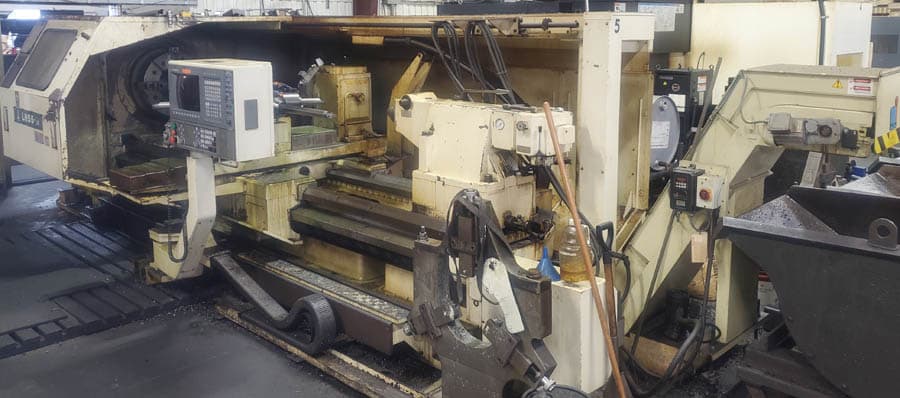

Okuma CNC For Sale

Being one of the leading manufacturers of reliable and efficient equipment, Okuma Corporation has gained its reputation for being a long lasting machine. Whether your machine shop is looking for a lathe for sale, big bore machines, CNC mill, vertical lathe, vertical mill or horizontal mill, Okuma has a number of models to choose from to meet the needs of today’s manufacturing processes. Our daily updated Okuma listings are ready for inspection.

Okuma Lathes

Okuma Genos L Series

The Okuma Genos L Series has been designed to be tough and accurate. These CNC turning center lathes come with sturdy base so that the CNC lathe does not shift during the high speed operations. Ideal for small to medium-sized parts, the Genos L Series offers:

- High-Speed Turning: Enhanced spindle speeds for efficient production.

- Thermo-Friendly Design: Minimizes thermal deformation for consistent precision.

- User-Friendly Interface: Intuitive controls for easy operation.

Okuma LB Series

The Okuma LB Series CNC lathes are designed for high production applications. These machines have high spindle power and better cutting tools to enable it perform complicated machining operations easily.

Key features include:

- Large Swing Capacity: Accommodates larger workpieces.

- Flexible Configuration: Tailorable options to suit specific production needs.

- Advanced OSP Control: Okuma's proprietary control system for seamless integration.

Okuma Multus Series

The Okuma Multus Series is the flagship of multitasking CNC lathes that incorporates the functions of both turning and milling. The Multus Series is ideal for the finishing operations of various part machining, and supports a lower turret that minimizes cycle time.

Highlights of the series include:

- Multitasking Capability: Carry out turning, milling and drilling operations with a single machine.

- B-Axis Milling Head: Enables cutting at any angle and creation of intricate shapes and forms.

- High Precision: Can deliver very small dimensions with high precision.

- Thermo-Friendly Concept: It helps to maintain a consistent machining performance by controlling thermal deformation.

- OSP-P Control System: Enhanced control options for optimum scheduling and processing functions.

The Multus Series is ideal for scenarios where small parts are required, namely, aerospace, automotive and medical device industries. These machines are useful in that they combine several processes into one, thereby cutting down the lead time.

Okuma Vertical Mills

Okuma Genos M Series

The Genos M Series of vertical mills are ideal for applications where accuracy is critical. The Okuma Genos has rigidity and thermal stability incorporated in it to enhance its performance.

Highlights of the series:

- Compact Footprint: Space-saving design without compromising on functionality.

- High-Precision Spindles: Ensures excellent surface finishes.

- Eco-Friendly Operation: Energy-efficient features reduce operational costs.

Okuma MB-V Series

For those who require higher milling performance, the MB-V Series is designed to offer the best performance. These machines are ideal for die/mold applications and complex part machining:

- High-Speed Machining: Rapid feed rates for increased productivity.

- 5-Axis Compatibility: Enhanced versatility for intricate machining.

- Thermal Stability: Maintains accuracy over long production runs.

Okuma Horizontal Mills

Okuma MA-H Series

The MA-H Series horizontal mills are designed for heavy duty cutting and powerful machining. They are suitable for large parts and challenging materials:

- Robust Construction: Handles high-torque applications.

- Automatic Pallet Changer: Increases efficiency with continuous operation.

- Advanced Chip Management: Keeps the workspace clean for optimal performance.

Enhance Functionality with Extra Options

Okuma machines can be customized with a variety of options to expand their capabilities:

- Renishaw Probing Systems: To ensure that the measurements taken are accurate also to ensure that they parts are properly aligned.

- Automation Solutions: Such as robotic loaders for unattended use, and Automatic Tool changers (ATC)

Other tools include enhanced CNC controls, parts catcher, Chip conveyor, Bar Feeder, Live Tooling, and Custom tailstock.

Okuma vs. Other Brands

Compared to other manufacturers like Haas, Mazak, and Doosan, Okuma machinery stands out for its:

- Durability: Designed for long term use with less time being required to fix or maintain them.

- Control Systems: All the proprietary OSP controls adopted into OptConnect are compatible and easy to use by the subscribers.

- Service and Support: The company offers a superb customer care service and mechanical support department.

Other brands may perhaps have similar features in the market but what makes Okuma different is the corporate focus on quality and innovation.

Why Buy a Used Okuma CNC Machine from Premier Equipment

Purchasing a used Okuma CNC machine from Premier Equipment means that you are getting value and the right equipment for your job. At Premier Equipment we deal with pre-owned machines with years of experience in buying and selling Okuma machines.

Benefits include:

- Cost Savings: Buy high-end CNC machines for much less than the initial price of brand new machines.

- Expert Inspection: Every machine is then checked by experienced professionals.

- Wide Selection: Used Okuma machine listings updated daily.

When you decide to purchase a used Okuma, Our team is ready to help you find the right model and tools to start your production as soon as possible. Speak to our Okuma brand CNC experts today!

Buy an Okuma CNC Machines

Currently, Okuma CNC machines are one of the best investments one can make in the manufacturing industry. The stronger engineering, more options for customization, and outstanding back up make them favorites of professionals in the field. So, when scaling up or replacing existing machining features, think about convincing advantages of using Okuma equipment.

CNC Lathes (2-Axis & Multi-axis)

| Machine Model |

Travel (X, Y, Z) |

Spindle |

| Okuma LB2000EX III |

225 mm (X-axis) x 1,000 mm (Z-axis) |

3,800 RPM, 22 kW |

| Okuma LT2000 EX |

225 mm (X-axis) x 1,020 mm (Z-axis) |

5,000 RPM, 15 kW |

| Okuma LB3000EX II |

300 mm (X-axis) x 1,200 mm (Z-axis) |

4,000 RPM, 30 kW |

| Okuma LU3000 EX |

370 mm (X-axis) x 1,040 mm (Z-axis) |

4,200 RPM, 37 kW |

| Okuma LB4000EX III |

400 mm (X-axis) x 2,050 mm (Z-axis) |

2,800 RPM, 30 kW |

| Okuma LU35 II |

500 mm (X-axis) x 1,500 mm (Z-axis) |

2,800 RPM, 26 kW |

| Okuma LU45 II |

560 mm (X-axis) x 2,250 mm (Z-axis) |

2,200 RPM, 37 kW |

CNC Flat-Bed Lathes

| Machine Model |

Travel (X, Z) |

Spindle |

Swing Over Bed |

Distance Between Centers |

Chuck Size |

| Okuma LH-35N |

610 mm (X-axis) x 1,524 mm (Z-axis) |

2,200 RPM, 30 HP |

610 mm (24") |

1,524 mm (60") |

15" |

| Okuma LH-55N |

670 mm (X-axis) x 2,997 mm (Z-axis) |

500 RPM, 37/30 kW |

1,100 mm (43.3") |

3,000 mm (118") |

24" |

CNC Vertical Machining Center 5-Axis

| Machine Model |

Travel (X, Y, Z) |

Spindle |

| Okuma Cadet Mate |

30" x 16" x 18" |

7,000 RPM, 15 HP |

| Okuma MX-45VAE |

30" x 18.8" x 17.72" |

7,000 RPM, 10 HP, CAT40 taper |

| Okuma MC40A |

32" x 16" x 20" |

6,000 RPM, 20 HP, CAT40 taper |

| Okuma MC-50VA |

40" x 20" x 20" |

6,000 RPM, 20 HP, CAT40 taper |

| Okuma MC-60VAE |

60" x 26" x 24" |

4,000 RPM, 30 HP, CAT50 taper |

| Okuma MX-45VB |

30" x 18" x 20" |

7,000 RPM, 20 HP, CAT40 taper |

| Okuma MX-55A/B |

41" x 22" x 22" |

7,000 RPM, 30 HP, CAT50 taper |

| Okuma MC-V4020 |

40" x 20" x 20" |

10,000 RPM, 20 HP, CAT40 taper |

| Okuma MB-46V |

36.22" x 18.11" x 18.11" |

15,000 RPM, CAT40 taper |

| Okuma MB-56V |

42.13" x 22.05" x 22.05" |

15,000 RPM, CAT40 taper |

| Okuma MB-66V |

59.06" x 26.18" x 22.05" |

12,000 RPM, CAT40 taper |

CNC Horizontal Machining Center

| Machine Model |

Travel (X, Y, Z) |

Spindle |

| Okuma MA-400HA |

22.04" x 24.8" x 26.77" |

10,000 RPM, CAT 40 |

| Okuma MC-500H |

31.50" x 29.53" x 31.50" |

6,000 RPM, CAT 50 |

| Okuma MA-400H |

22.04" x 24.8" x 26.77" |

15,000 RPM, CAT 40 |

| Okuma MA-500H |

29.53" x 29.53" x 31.50" |

12,000 RPM, CAT 50 |

| Okuma MA-600H |

39.37" x 35.43" x 37.40" |

6,000 RPM, CAT 50 |

| Okuma MA-800H |

47.24" x 39.37" x 47.24" |

6,000 RPM, CAT 50 |

| Okuma MB-4000H |

22.04" x 24.80" x 26.77" |

15,000 RPM, CAT 40 |

| Okuma MB-5000H |

29.53" x 29.53" x 31.50" |

15,000 RPM, CAT 40 |

| Okuma MB-8000H |

47.24" x 39.37" x 47.24" |

6,000 RPM, CAT 50 |

| Okuma Millac-44H |

24.8" x 22.04" x 22.04" |

15,000 RPM, CAT 40 |

| Okuma MILLAC-800VH |

39.37" x 35.43" x 33.46" |

6,000 RPM, CAT 50 |

| Okuma MILLAC-1000VH |

39.37" x 35.43" x 33.46" |

6,000 RPM, CAT 50 |

| Okuma MX-40HA |

22.04" x 24.80" x 26.77" |

10,000 RPM, CAT 40 |

| Okuma MX-50HB |

31.50" x 31.50" x 31.50" |

10,000 RPM, CAT 50 |

| Okuma MX-60HB |

35.43" x 31.50" x 31.50" |

10,000 RPM, CAT 50 |

| Okuma MC-800H |

39.37" x 35.43" x 31.50" |

6,000 RPM, CAT 50 |

Okuma Customer Care and Technical Support

Okuma’s customer support

for service - https://www.okuma.com/service or call 704-588-7000

Okuma’s customer support for p

arts - https://www.okuma.com/okuma-common-exchange-parts

Okuma Educational Resources

The Okuma Machine Tool Academy is an example of Okuma's dedication to education. There are a number of courses available in this program that cover a wide variety of topics, including programming, operation and maintenance

. - https://www.okuma.com/okuma-machine-tool-academy

Okuma Guides and Manuals

It is easy to access machine manuals with Okuma's OSP CNC control system. A simple USB drive allows operators to easily upload third party PDFs directly to their machines or find pre installed manuals. This is a feature that guarantees the critical information is always with operator’s finger tips, reducing downtime and improving efficiency.

- https://www.okuma.com/videos/osp-cnc-control-finding-and-uploading-manuals

Okuma Online Resources

- Okuma America Website: Product information, case studies, blog posts, white papers, webcasts.

- Okuma YouTube Channel: Includes video tutorials, machine demonstrations, and industry insights.