Used CNC Lathe For Sale

At Premier Equipment we deliver high-quality used CNC lathe from major manufacturers to provide total lathe machining solutions for businesses that need dependable performance. Our extensive CNC inventory contains precision CNC lathes which integrate advanced capabilities like multi-axis turning and automated tool technology as well as sophisticated controls supporting diverse industrial applications.

Our expert team examines each CNC lathe we have in inventory so that we can guarantee maximum performance while delivering optimal value. Our daily refreshed inventory of used CNC turning machines offer many options for manufacturing facilities and machine shops of all sizes. Gping for a used lathe offers budget-friendly options that match new equipment performance standards.

CNC Lathe Brands and Models

The CNC lathe market features a wide range of machint tools from multiple manufacturers which serve different production requirements and financial constraints. Our CNC lathe inventory includes brands like Haas, Mazak and Okuma which deliver their reputation for premium technology and dependable performance.

Below is a list of popular CNC lathe brands:

| Brand |

Model Series |

Description |

| Mazak |

QT-Primos Series |

Compact, efficient lathes designed for high precision in small parts production. Ideal for entry-level CNC users. |

|

Quick Turn Series |

The Quick Turn Series includes lathes that deliver quick machining capabilities to address various manufacturing needs, particularly complex shapes. |

|

Hyper Quadrex Series |

The Hyper Quadrex Series contains multi-tasking lathes built with two spindles and turrets, which enhance production speeds while providing greater operational flexibility. |

|

Integrex Series |

The Integrex Series are multi-tasking machines that combine turning and milling operations for single-part machining in a single setup. |

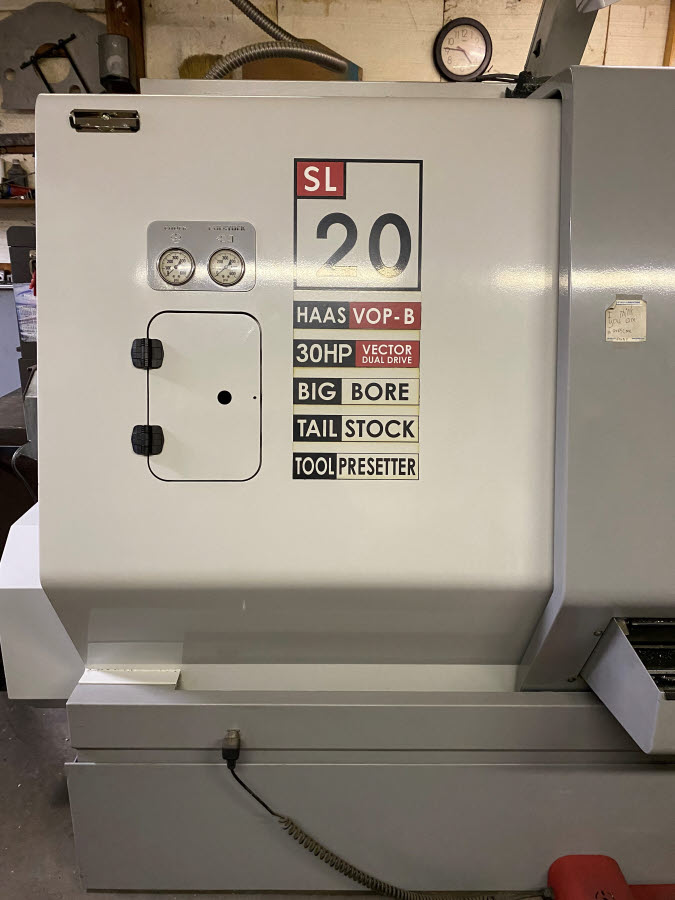

| Haas |

ST Series |

Haas offers the ST Series, which are robust, reliable lathes designed for high production with a variety of sizes and configurations. They are ideal for a range of turning operations. |

|

DS Series |

Dual-spindle lathes designed to increase throughput with simultaneous machining on both spindles, suited for complex part manufacturing. |

|

TL Series |

The TL Series from Haas are toolroom lathes ideal for prototyping, production runs, and educational purposes, with manual and CNC control. |

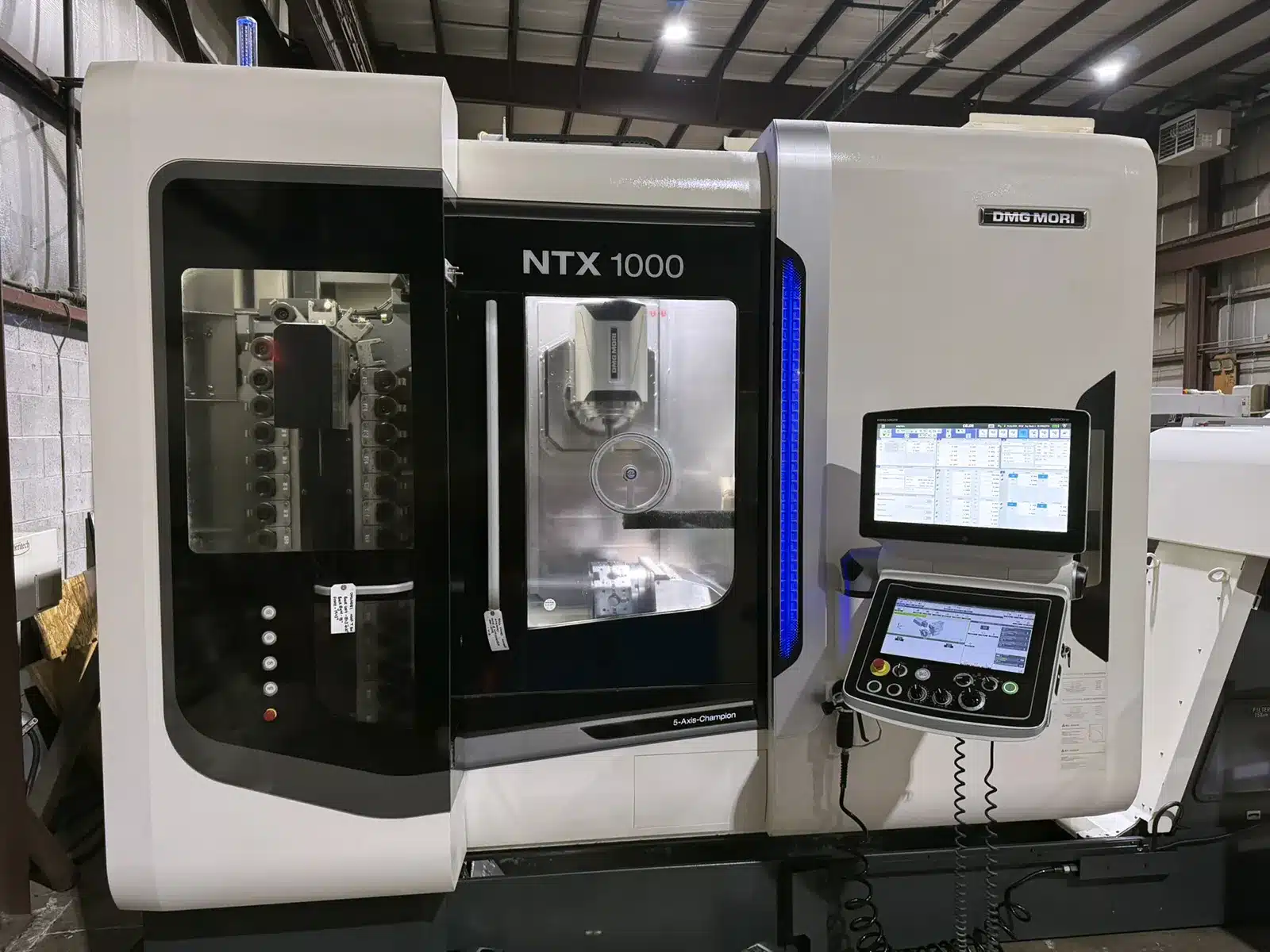

| DMG Mori |

NLX Series |

DMG Mori's NLX Series High-precision lathes enables advanced turning of complex parts together with demanding materials. Well-suited for automotive and aerospace industries. |

|

CLX Series |

The CLX Series of entry-level lathes delivers high performance to produce basic parts alongside moderately complex pieces with priority on equipment reliability and affordability. |

|

CTX Series |

DMG Mori's CTX Series are multi-functional lathes designed for machining complex parts in a single setup, offering flexibility and high productivity. Ideal for high-mix, low-volume production. |

| Okuma |

LB EX Series |

The LB EX Series lathes are highly rigid lathes designed for heavy-duty cutting and long-term reliability, with advanced control systems. |

|

GENOS L Series |

The GENOS L Series offers an affordable line of high-quality lathes that support industrial productivity and usability across various market sectors. |

|

MULTUS Series |

Okuma's MULTUS Series Multi-tasking lathes fulfill three operations in one setup to produce complex parts efficiently. |

| Doosan |

Lynx Series |

Doosan's Lynx Series Compact features as high-rigidity lathes which enable precise small part mass production applications in automotive industry. |

|

Puma Series |

The Puma Series Versatile lathes are medium to large machine tools which provide durability combined with high-demand performance in challenging industrial conditions. |

|

TT Series |

Doosan's TT Series Twin-turret lathes improve both production speed and machine versatility to handle complex parts simultaneously. |

Discover Your Ideal Lathe

Our inventory of used CNC lathes features different lathe models which have been specifically developed to maximize operational productivity, precision, and efficiency. Our machines exists to serve customers who need CNC turning capabilities along with milling or both manufacturing processes. Our CNC lathe machine inventory features multiple features that optimize your machining operations.

When looking for a CNC lathe for sale on Premier Equipment, Many of our selection of used CNC turning cutting tool machines come with options like live tooling, bar feeder, single spindle and multi-spindle, from top brands like Haas, Fanuc, Daewoo, Miyano and Mori Seiki lathes.

| Feature |

Description |

| RPM (Rotational Speed) |

Your cutting efficiency depends on RPM (Rotational Speed) as this parameter shapes both your end product quality and total performance outcome. |

| Tailstock |

The tool extends workpiece length support so operations remain stable. |

| Sub Spindle |

The Sub Spindle enables additional processing functions directly on the same component through a single setup without requiring any part movements and suits complex and difficult production tasks. |

| Bar Capacity |

The Bar Capacity Specification helps determine the upper and lower constraints on raw material dimensions. |

| Chuck Size |

The maximum specification of the chuck allows users to understand its grip capacity potential. |

| Max Turning Diameter |

The maximum machine turning diameter determines the largest possible component dimension for production. |

| Max Turning Length |

Maximum workpiece capacity through the parameter called Max Turning Length. |

Explore Our Extensive Range of CNC Lathes

SWISS CNC LATHES

Precision engineering defines the Swiss CNC lathes, as they deliver flawless precision manufacturing of workpieces. Fast cycle times from Swiss CNC lathes help organizations achieve operational efficiency by finishing tasks rapidly to increase productivity levels. Swiss CNC lathe brands include Citizen and Tsugami

2 AXIS CNC LATHES:

A 2-axis CNC lathe moves tools in two dimensions using Xand Z axes to control the position of the workpiece and its length. The fundamental machines deliver part production by performing basic turning, facing, and threading operations.

The 2-axis CNC lathe operates with durability and precision on basic turning functions while maintaining a lower pricing point for conventional manufacturing needs.

3 AXIS LATHES AND CNC TURNING CENTERS:

The 3-axis CNC lathe system executes basic machining functions by moving along the X, Y, and Z axes to produce accurate turning and facing processes and contouring capabilities.

These CNC lathe machines use a main spindle to rotate workpieces while tool turrets traverse three linear axes to produce cylindrical parts that incorporate features such as threads, tapers, and precise dimensions.

4 AXIS LATHES:

The 4-axis CNC lathe system handles simple turning functions in addition to complex milling procedures to create elaborate manufacturing possibilities from a single operating position. Machines with turning spindles facilitate disc-shaped milling and drilling and contouring operations through their Y-axis control system. The additional axis of this machine provides the potential to make complex parts with off-set components and contoured features.

5 AXIS LATHES:

The

5-axis CNC lathe presents the most advanced turning functionality through its combination of three linear axes (X, Y, Z) and two rotational axes (B, C) for complex machining operations.

The advanced setup of simultaneous 5-axis machining allows the production of complex contours, undercuts, and angled features during a single operation.

The combination of B-axis tool carrier tilting and C-axis rotation enables these machines to provide unmatched versatility, making them suitable for aerospace, medical, and precision engineering applications that require superior finishes and tight tolerances for complex geometric components.

Why Choose Premier Equipment?

Your satisfaction stands as our highest priority at Premier Equipment. Our extensive CNC lathe selection enables you to choose exactly what you need for your projects and financial constraints.

Our inventory includes

CNC machines from best renowned brands including Haas Mori Seiki Amada DMG Mori and Okuma. Our experts will assist you to select the perfect bar size and chuck size and CNC control and complete machine choice from our turning center collection and used CNC lathe inventory.

Premier Equipment stands ready to boost your manufacturing capabilities through our exceptional range of CNC equipment.

FAQ

What are the specs to evaluate when considering a used CNC lathe?

When looking through the used CNC lathe selection at Premier Equipment, you should think about several important features and how they relate to your particular machining needs. The "

what to look for" part of this discussion might start with spindle speed (RPM). When it comes to turning workpieces, the faster the spindle goes, the more work it can get through in a given time, and the more consistently it can do so with higher quality. We should also consider whether the lathe has a tailstock, which is important for not just turning but also facing, and for anyone making more precise kinds of parts.

Which CNC lathe brands can I expect to find in Premier Equipment's used inventory?

Premier Equipment stocks a wide variety of used CNC lathes from many of the industry's most leading and reliable manufacturers. Some of the more popular brands that we have in our inventory include Mazak (with series like QT-Primos, Quick Turn, Hyper Quadrex, and Integrex), Haas (including ST, DS, and TL series), DMG Mori (featuring NLX, CLX, and CTX series), Okuma (such as LB EX, GENOS L, and MULTUS series), and Doosan (including Lynx, Puma, and TT series).

How does Premier Equipment assure the quality and performance of their used CNC lathes?

A thorough inspection system is employed by Premier Equipment, during which each used CNC lathe is evaluated by an expert. Our experts ensure that the CNC machinery works at the highest possible quality. That said, inspectors look for many different things. Here is a non-exhaustive list of some of the aspects concerning which our inspectors are experts:

- Check all internal mechanical parts for wear.

- Inspect all drive components.

- Evaluate all axis motions.

- Check electrical components.

- Run performance tests.

- Verify the machine's overall integrity.

What are the primary reasons why a business might choose to purchase a used CNC lathe?

Acquiring a pre-owned CNC lathe provides a number of beneficial payoffs. It can be a far less expensive option for businesses of all stripes, offering the chance to snag top-tier performance and modern features from reputable manufacturers without the sizey price tag attached to fresh-off-the-line machines.